We offer key solutions to companies producing a wide range of bakery products and specialty fats, such as emulsified or non-emulsified shortenings, bakery baking fats, cake shortenings, table margarines, cake margarines, butterfat spreads, butterfat-free spreads, cocoa butter substitutes, puff shortenings, cream shortenings, puff margarines, and more.

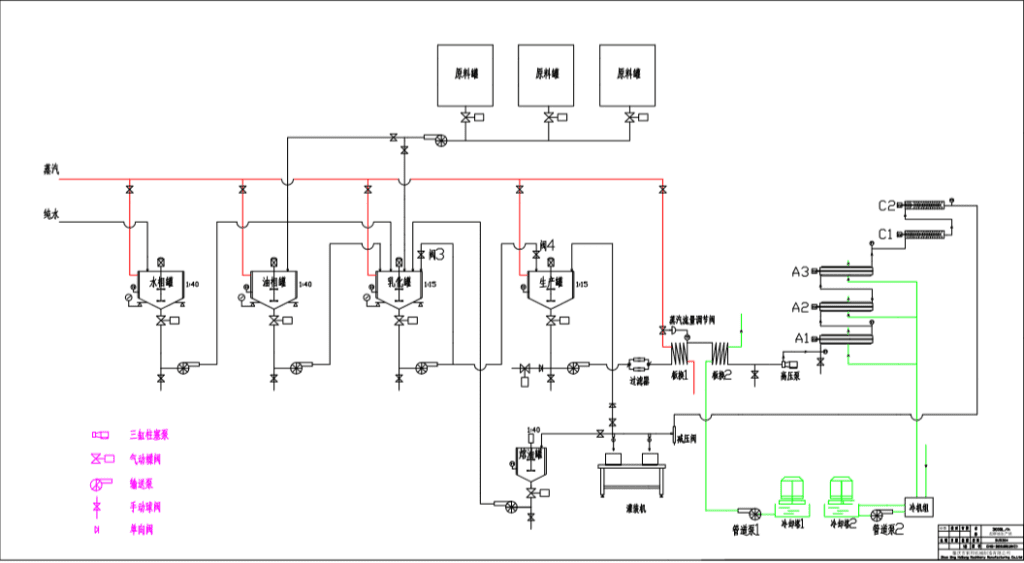

This unit primarily consists of a plate heat exchanger, kneading unit, filling machine, high-pressure pump, and PLC automatic control system. It is primarily used in the production of various viscous materials, such as margarine, shortening, and animal and vegetable oils and fats.