Make an Enquiry

About Us

Welcome to Bang Win Thermal

With over two decades of dedicated experience in thermal equipment manufacturing, Bang Win Thermal stands at the forefront of industrial heat exchange and energy efficiency solutions. Since expanding to the global market in 2017, we have earned the trust of clients across Asia, Europe, South America, and beyond — delivering reliable, high-performance thermal systems built to meet the unique challenges of modern industry.

Bang Win Thermal

Welcome to Bang Win Thermal, With over 20 years of experience in manufacturing and a proven track record in the global market since 2017, we deliver world-class thermal solutions tailored to your industrial needs.

Main Products

Heat Exchanger

Plate Heat Exchanger; Fin Tube Heat Exchanger; Shell And Tube Heat Exchanger; Plate Fin Heat Exchanger.

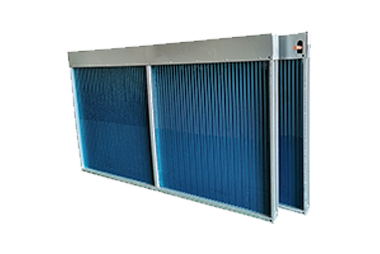

Plate Heat Exchanger

Compact and efficient Plate Heat Exchanger for optimal heat transfer in industrial and HVAC systems.

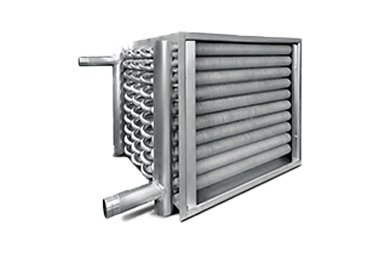

shell and tube heat exchanger

Durable Shell and Tube Heat Exchanger for efficient heat transfer in industrial, chemical, and energy applications.

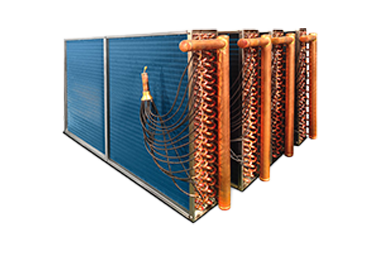

Fin Tube Heat Exchanger

High-performance Fin Tube Heat Exchanger for enhanced heat transfer in HVAC, power, and industrial systems.

Tube Finned Heat Exchanger

Efficient Tube Finned Heat Exchanger designed for superior thermal performance in HVAC and industrial applications.

Evaporator

High-efficiency Evaporator for reliable cooling and heat exchange in refrigeration and industrial systems.

Condenser

Durable and efficient Condenser for optimal heat rejection in refrigeration, HVAC, and industrial cooling systems.

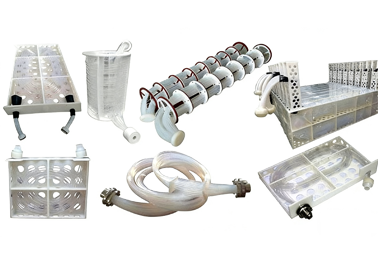

PTFE Heat Exchanger

High-performance PTFE heat exchangers designed for strong corrosion resistance, chemical stability, and long service life in aggressive industrial environments.

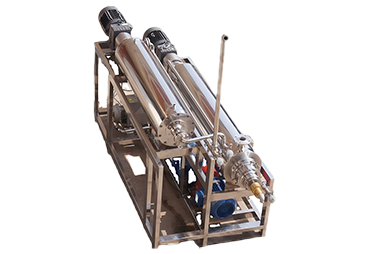

Our scraped surface heat exchanger/Votator can be manufactured in a variety of configurations and materials so that each unit can be assembled to meet the specific processing requirement of each application and each product.

Main Products

Fin Tube

Extruded fin tube; Low fin tube; Spiral fin tube; High frequency welding fin tube; Laser welded fin tube;G Fin Tube

extruded fin tube

High-quality Extruded Fin Tube for excellent heat transfer performance in air-cooled heat exchangers and industrial systems.

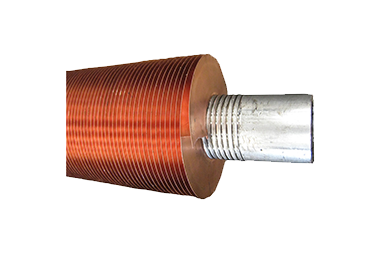

g fin tube

Reliable G Fin Tube for efficient heat transfer and long service life in air coolers and heat exchanger applications.

High frequency welding fin tube

High-performance Fin Tube Heat Exchanger for enhanced heat transfer in HVAC, power, and industrial systems.

Laser welded fin tube

Precision Laser Welded Fin Tube offers superior heat transfer, corrosion resistance, and durability for industrial applications.

Spiral fin tube

Spiral Fin Tube for superior heat transfer efficiency and durability in air-cooled heat exchangers and industrial systems.

low fin tube

High-efficiency Low Fin Tube for enhanced heat transfer in condensers, air coolers, and industrial applications.

Main Products

Fin Tube Machine

Extruded fin tube machine; Low fin tube machine; Spiral fin tube machine; High frequency welding fin tube machine; Laser welded fin tube machine;H type fin tube machine

extruded fin tube machine

Extruded Fin Tube Machine for high-precision production of finned tubes with superior heat transfer performance.

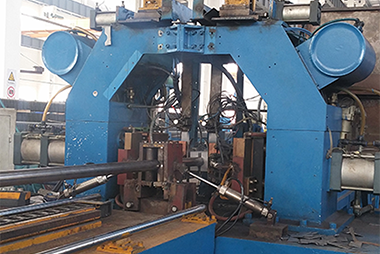

Laser welding fin tube machine

Laser Welding Fin Tube Machine for precise, durable fin-to-tube bonding in high-efficiency heat exchanger production.

HF welding fin tube machine

High-performance Fin Tube Heat Exchanger for enhanced heat transfer in HVAC, power, and industrial systems.

Low fin tube machine

Low Fin Tube Machine for efficient manufacturing of low-fin tubes with enhanced heat transfer performance.

spiral fin tube machine

Spiral Fin Tube Welding Machine for precise, high-efficiency production of spiral finned heat exchanger tubes.

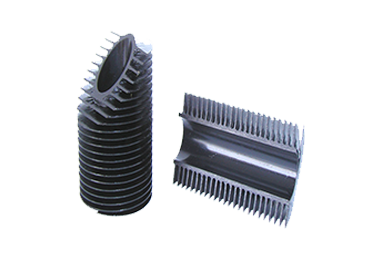

L type fin tube machine

L-Type Fin Tube Machine for accurate fin forming and efficient production of L-fin heat exchanger tubes.

H-Type Fin Tube Machine

H-Type Fin Tube Machine for precise fin forming and high-efficiency production of heat exchanger tubes.

Product Application

Power Generation

Petrochemical

HVAC

Chemical & Pharmaceutical

Food & Beverage

Industrial Drying

Company Advantage

Bang win Thermal’s heat exchangers have a lot of advantages, such as High Efficiency, Energy Savings, Compact Design, Multi-Industry Use, Eco-Friendly, Durable Materials, Modular Flexibility, Precise Control, Low Maintenance, Extreme Adaptability, etc.

Why Chooes Us

26+ Years Manufacturing Experience

ISO Certified Factory

Customized Engineering Support

Global Clients from 20+ Countries

FAQ

❓ What is a finned tube heat exchanger?

A finned tube heat exchanger uses extended surface tubes (fins) to increase the contact area with air or gas, enhancing heat transfer efficiency in heating and cooling applications

❓ What materials are your finned tubes made from?

We manufacture finned tubes using carbon steel, stainless steel, copper, aluminum, and alloy materials. The selection depends on your operating environment and thermal requirements.

❓ Can you manufacture custom designs?

Yes. We offer OEM/ODM services and can produce according to your technical drawings, performance specs, or even reverse-engineer from samples.

❓ How long is your lead time?

Standard lead time is 10–20 working days. For urgent or high-volume orders, we offer expedited production upon request.

❓ What is your company’s experience in this industry?

With over 20 years of manufacturing experience and global clients since 2017, we are a trusted supplier in the field of industrial heat transfer. Our factory is ISO certified, and our team ensures consistent quality and performance.

❓ What support do you offer after delivery?

We provide full after-sales support including technical consultation, installation guidance, and quick-response customer service. Spare parts and maintenance advice are also available.