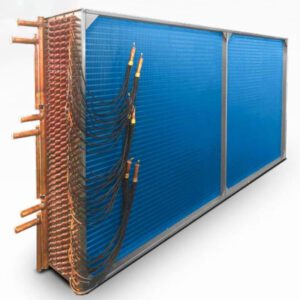

What is Finned Tube Heat Exchanger?

Fin Tube Heat Exchanger consist of small tubes located within a cylindrical shell. These finned pipes are positioned within a cylinder as a bundle, allowing various gases or liquids to circulate in a process of heat exchange that either warms or cools an element. Their objective is to recover or reject heat, or to sterilize, pasteurize, fractionalize, distill, crystallize, or control a fluid or process fluid.

It is often categorized as a compact heat exchanger to emphasize its relatively high heat transfer surface area to volume ratio. The exchanger is widely used in many industries, including the aerospace industry, as well as in cryogenics where its ability to facilitate heat transfer.

Features of Finned Tube Heat Exchanger

Compact Structure

Our fin-and-tube heat exchangers are compact and use “sandwich” channels containing fins to increase the unit’s efficiency,

including cross-flow and counter-flow and a variety of fin configurations such as straight, offset and corrugated fins .

Efficient Operation

They adopt advanced synchronous stratified flow cooling technology, using special corrugated fins for heat transfer,

increasing the contact area between fluid and air for adequate and rapid heat dissipation.

Corrosion Resistant

These heat exchangers feature thick-walled seamless stainless steel tubes that expand into copper fins with extruded full collars.

These fins ensure even distribution of fluids when in contact with different fluids and are resistant to corrosion by water, oil and gases.

Customizable

These fin-and-tube heat exchangers not only feature fins in a variety of materials, but also support custom designs,

including various fin patterns, bend densities, mounting structures and pipe connection schemes.

Reviews

There are no reviews yet.