Product Introduction:

Gas-fired (oil-fired) thermal oil boilers use gas, oil, or ethanol as fuel and thermal oil as the heat transfer medium. They can serve as high-temperature heat sources in various environments below 350℃ and are widely used in various industries requiring high-temperature heating or drying. This product features high temperature, low pressure, precise temperature control, and high thermal energy utilization. An optional steam generator can be added to produce saturated steam at pressures below 1.3MPa for user use. Our company’s newly developed YY(Q)W series thermal oil boiler is a product of years of design and manufacturing experience, incorporating advanced European technology and absorbing the successful experiences of domestic and international counterparts.

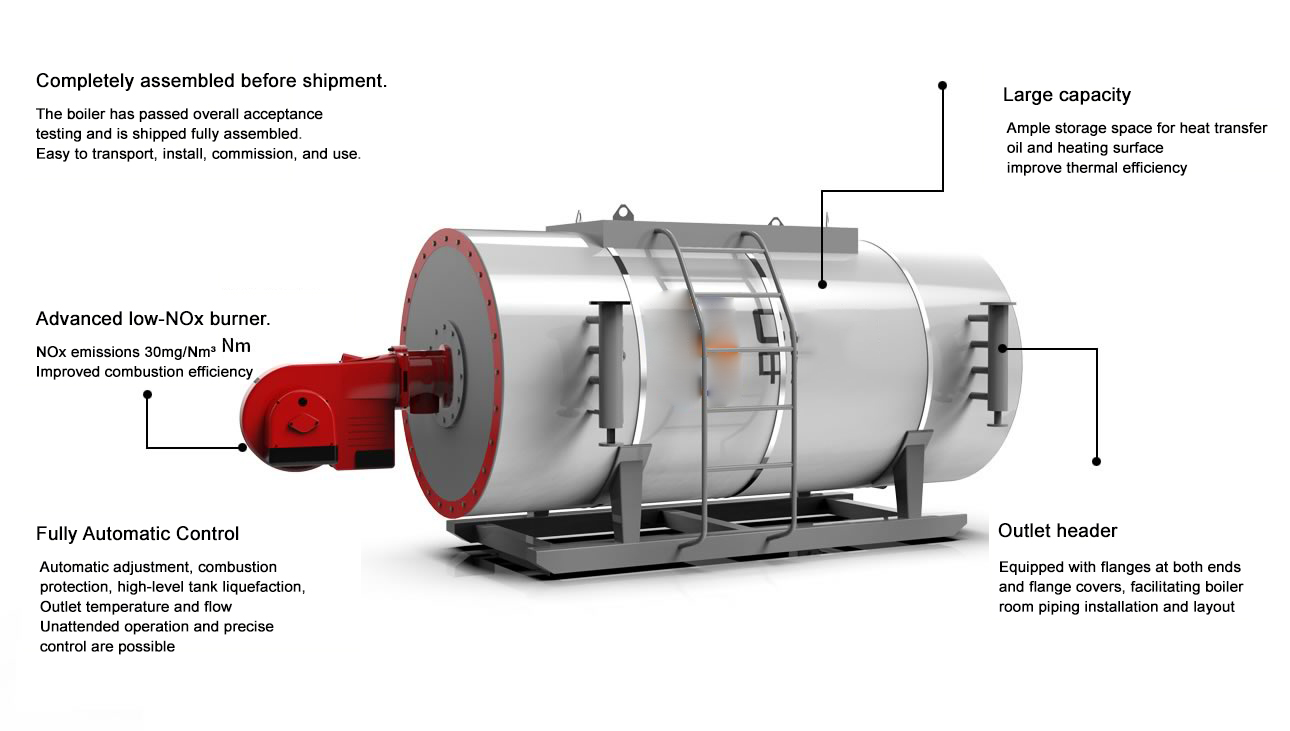

Product Features:

The product boasts practicality, economy, and safety. The system possesses the following performance characteristics:

Provides users with a stable high-temperature heat source; all our products have a 10% design margin.

The system features a high-efficiency, low-energy-consumption economic design, resulting in an overall thermal efficiency of over 94% for the thermal oil heater.

Features a furnace body structure that does not damage the heat carrier, significantly extending the service life of the heat medium.

Utilizes the most advanced automatic control methods in the domestic industry, ensuring the outlet temperature of the thermal oil main pipe is controlled within ±1℃.

Equipped with comprehensive safety detection devices to prevent dangerous operating conditions of the thermal oil heater.

The entire system is easy to maintain and inspect for each unit.

Working Principle:

The YY(Q)W series thermal oil heater (organic heat carrier heater) is a quick-installation horizontal forced-circulation oil (gas) thermal oil heater (organic heat carrier heater). This series of thermal oil heaters (organic heat carrier heaters) has a compact structure; the heating surface consists of inner, middle, and outer (or inner and outer) densely arranged circular tubes, with the inner tubes serving as the radiant heating surface. The inner and outer coils are convective heating surfaces.

Fuel burns and releases heat in the combustion chamber formed by the inner coils. After absorbing most of the heat through the radiant heating surface, the high-temperature flue gas enters the convective heating surface for heat exchange. The flue gas, after heat exchange, is discharged through the furnace body’s exhaust port and enters the air preheater for thorough heat exchange with the air. The flue gas then enters the condenser for heat exchange with water. Finally, the flue gas temperature drops below 100°C and is discharged into the atmosphere through the chimney.

| Skid-mounted series organic heat carrier furnace parameter table | |||||||

| Heating capacity: 10 kcal/h | 30 | 60 | 80 | 100 | 120 | 160 | |

| Rated power (MW) | 0.35 | 0.7 | 0.95 | 1.2 | 1.4 | 1.9 | |

| Rated working pressure | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | |

| Rated outlet temperature (MPa) | 300°C | 300°C | 300°C | 300°C | 300°C | 300°C | |

| Oil capacity | 0.237 | 0.64 | 0.7 | 0.92 | 1.07 | 1.58 | |

| Circulation flow rate (m³/h) | 28.354 | 56.7 | 76.96 | 97.2 | 118.46 | 153.9 | |

| Piping connection diameter (DN) | 80 | 100 | 100 | 125 | 125 | 150 | |

| Electrical control cabinet model | DK-350 | DK-700 | DK-950 | DK-1200 | DK-1400 | DK-1900 | |

| Installed capacity (KW) | 10 | 20 | 25 | 30 | 30 | 45 | |

| External dimensions (transportation) | Length (mm) | 6980 | 7680 | 8150 | 8650 | 9080 | 9880 |

| Width (mm) | 2650 | 2850 | 2950 | 3050 | 3050 | 3100 | |

| Height (mm) | 2650 | 3050 | 3660 | 3660 | 3660 | 3680 | |

| Maximum transport weight (T) | 5 | 8.26 | 9.68 | 10.94 | 11.63 | 13.42 | |

Reviews

There are no reviews yet.