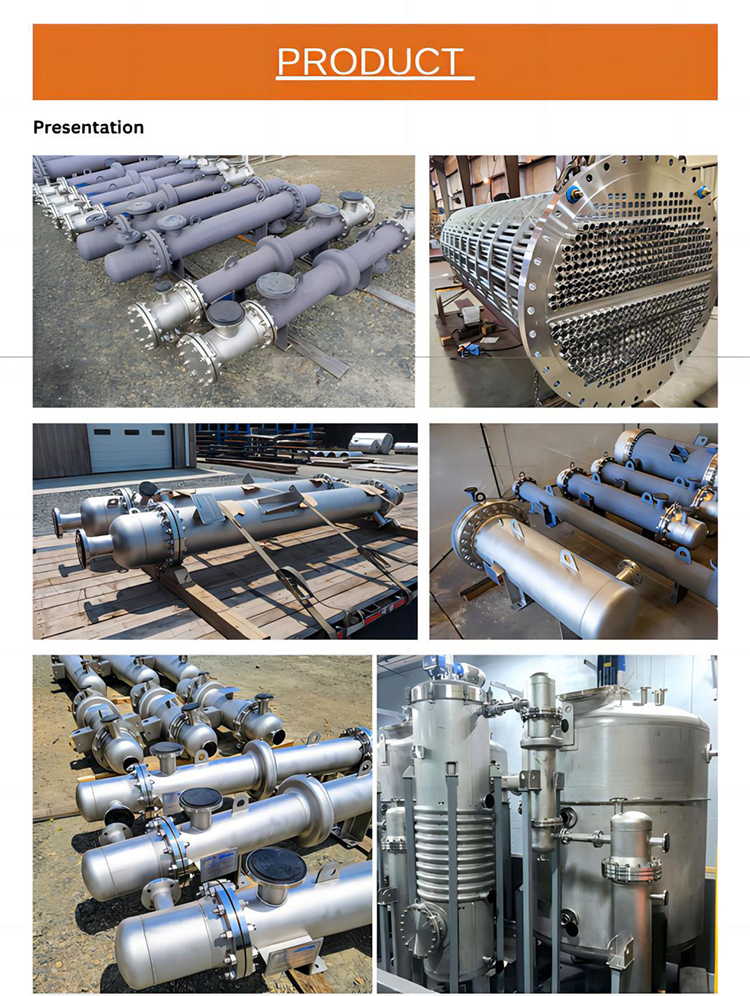

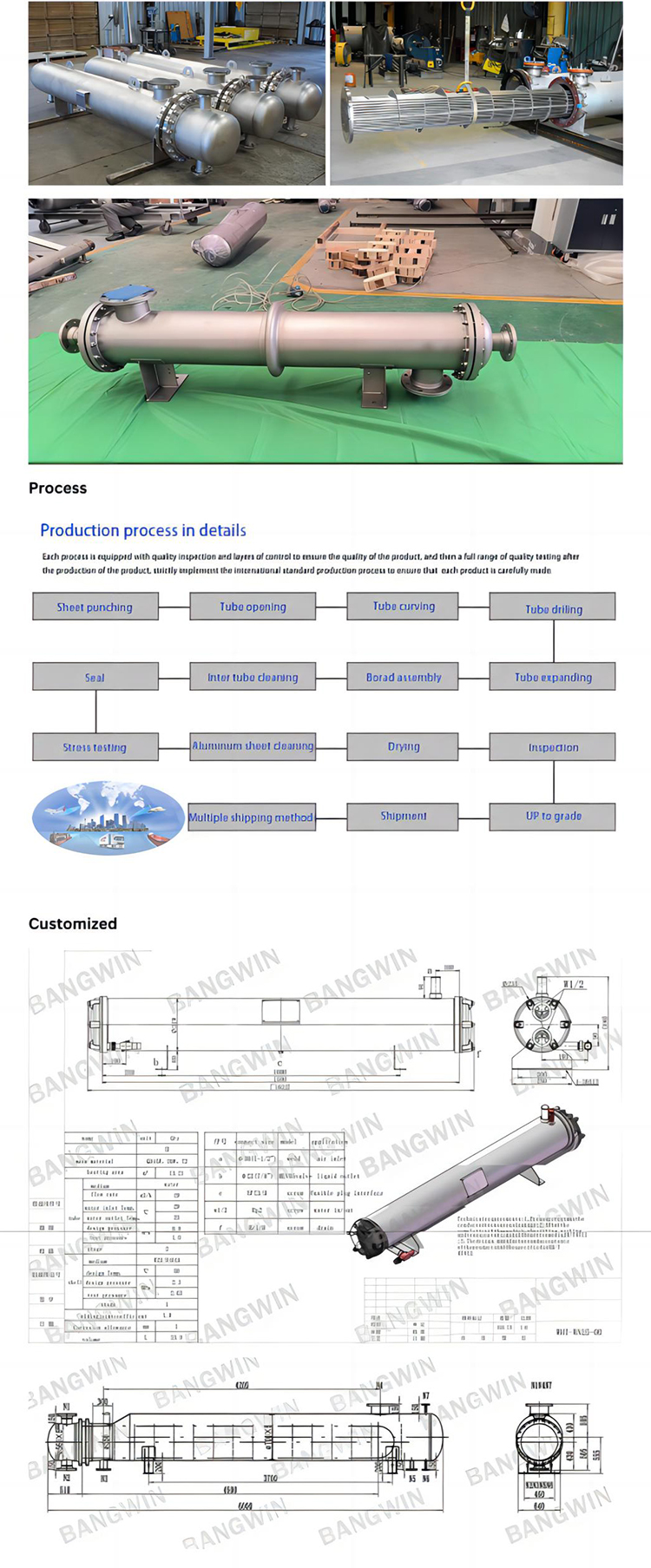

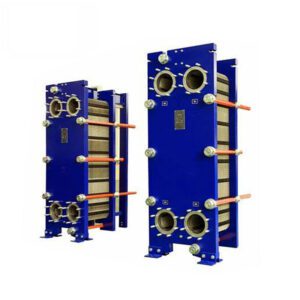

What is Shell Tube Heat Exchanger?

A shell-and-tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications. As its name implies, this type of heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a tube bundle, and may be composed of several types of tubes: plain, longitudinally finned, etc.

Features of Shell Tube Heat Exchanger

Sturdy Structure

The components of our shell and tube heat exchangers are made of extruded or welded stainless steel, carbon steel, titanium, copper or Inconel to prevent tube or shell bending and nozzle connection deformation, even when exposed to a wide temperature range.

Flexible to Use

The tube bundles of these shell and tube heat exchangers are not bound by the shell, and the floating heads can be freely expanded and contracted, so they are suitable for fluids with large temperature differences and can be used at high pressures of 6.4Mpa and high temperatures below 450°C.

Efficient Connection

They feature self-sealing quick-connect devices on all fluid connections, allowing hot and cold fluid flows to be connected in less than a minute and reducing fluid leaks and mixing errors.

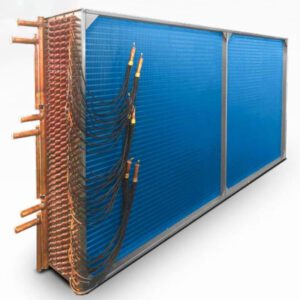

Rich Styles

These heat exchangers are available in a variety of styles, including single and multi-pass, U-tube, fixed tube, floating head and fixed tube types, with custom options in size, material and construction for different applications.

Reviews

There are no reviews yet.