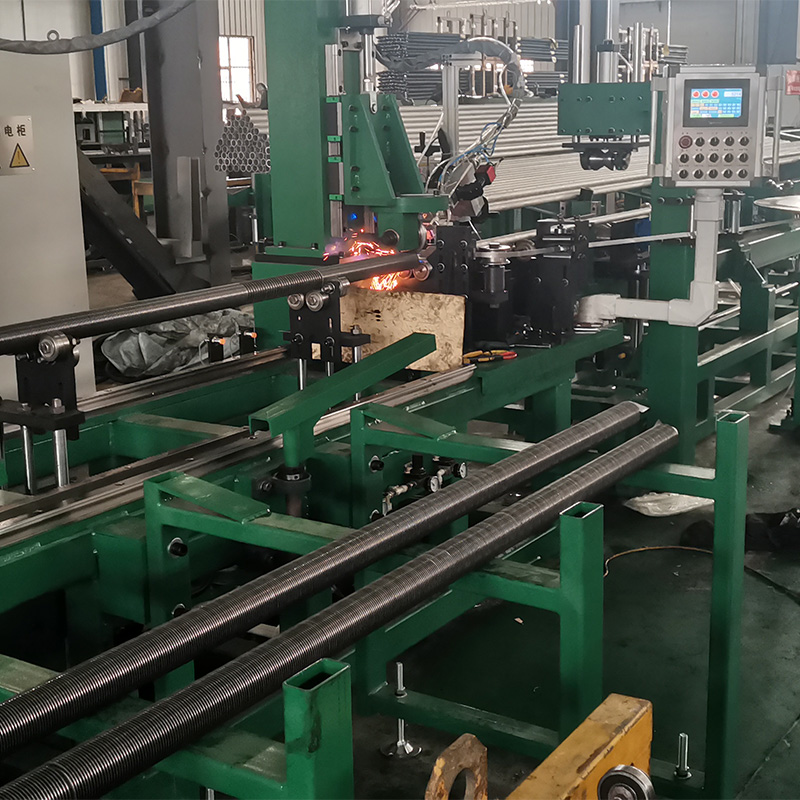

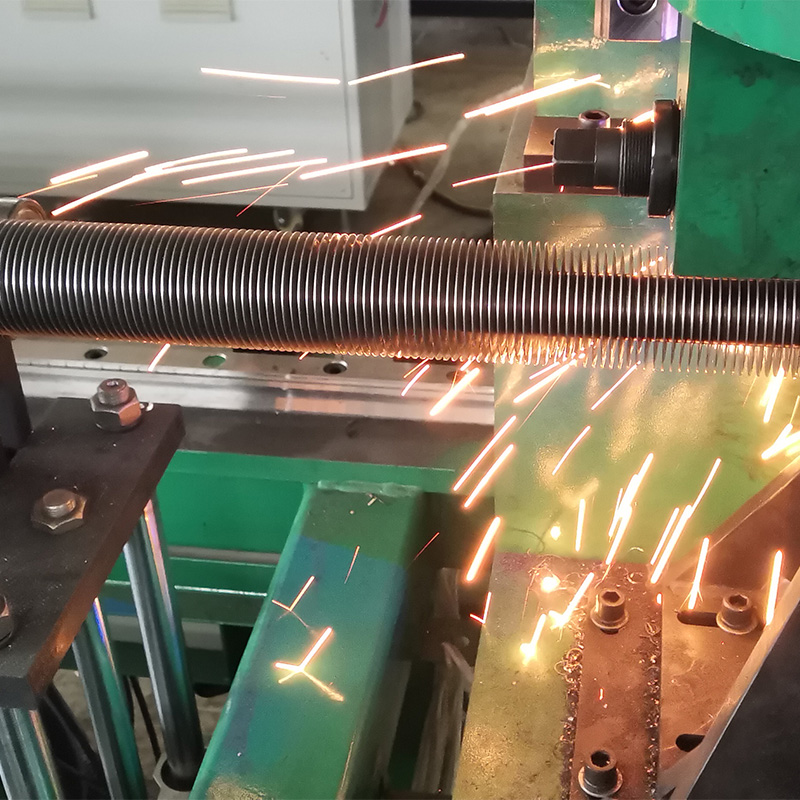

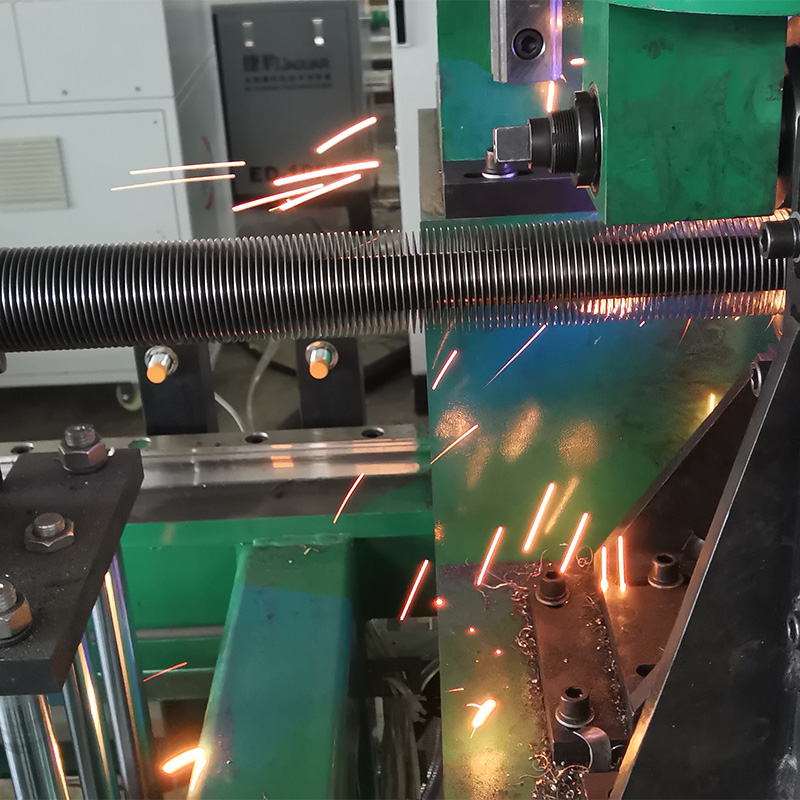

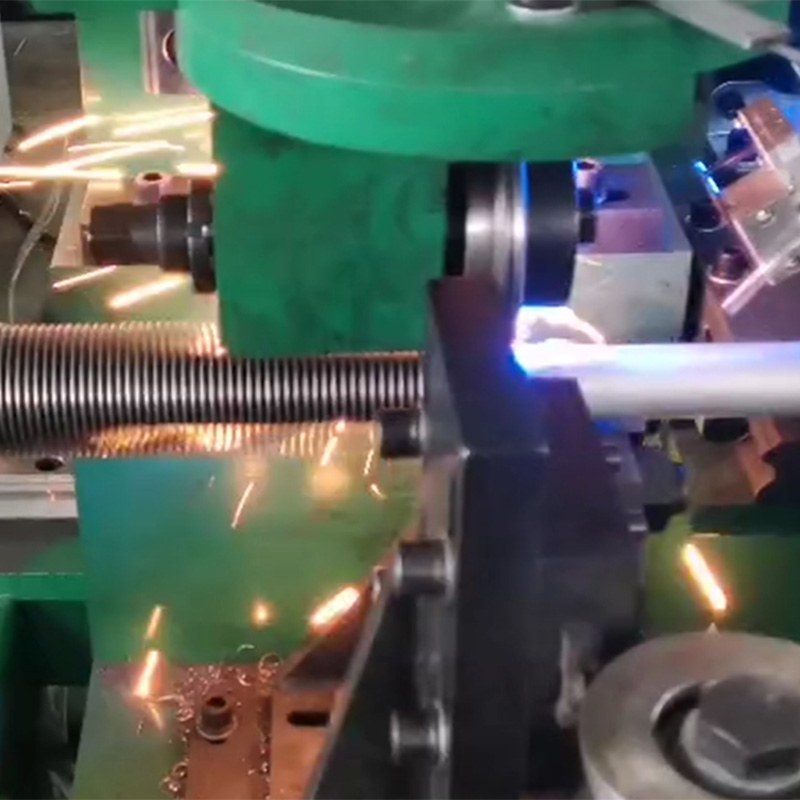

A Laser Welding Fin Tube Machine is a specialized industrial machine designed to manufacture high-performance finned tubes by welding fins onto tubes using a laser welding process. This method offers precise, strong, and clean welds, making it ideal for applications requiring high thermal conductivity and durability, such as power plants, petrochemical, HVAC, and refrigeration industries.

| Main Machine Dimensions (L×W×H) | 15000 × 1520 × 2330 mm |

| Tube Rack Dimensions (L×W×H) | 3550 × 950 × 1150 mm × 3 sections |

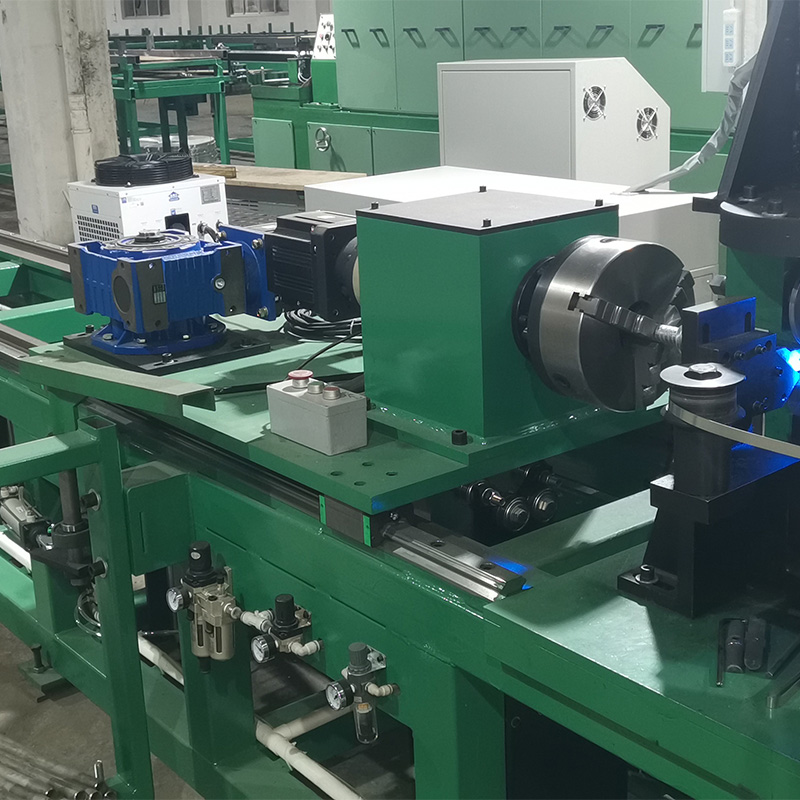

| Main Spindle Speed | 20 ~ 285 RPM |

| Precision | 0.1 mm |

| Fin Pitch | 2 ~ 30 mm |

| Fin Height | 5 ~ 30 mm (depends on base tube size) |

| Fin Thickness | 0.4 ~ 1.0 mm |

| Fin Material | Carbon steel, Stainless steel |

| Base Tube Outer Diameter | 15 ~ 104 mm |

| Base Tube Wall Thickness | ≥1.0 mm |

| Base Tube Material | Carbon steel, Stainless steel |

| Servo Motors | 7 kW + 3 kW (Mitsubishi) |

| PLC | Mitsubishi |

| Touch Screen | Weintek |

| Laser Source | 3 kW (MAX brand) |

| Welding Head | Raytools |

| Total Power | 20 kW |

| Power Supply | 3-phase 380V + N + PE |

Reviews

There are no reviews yet.