What is evaporator?

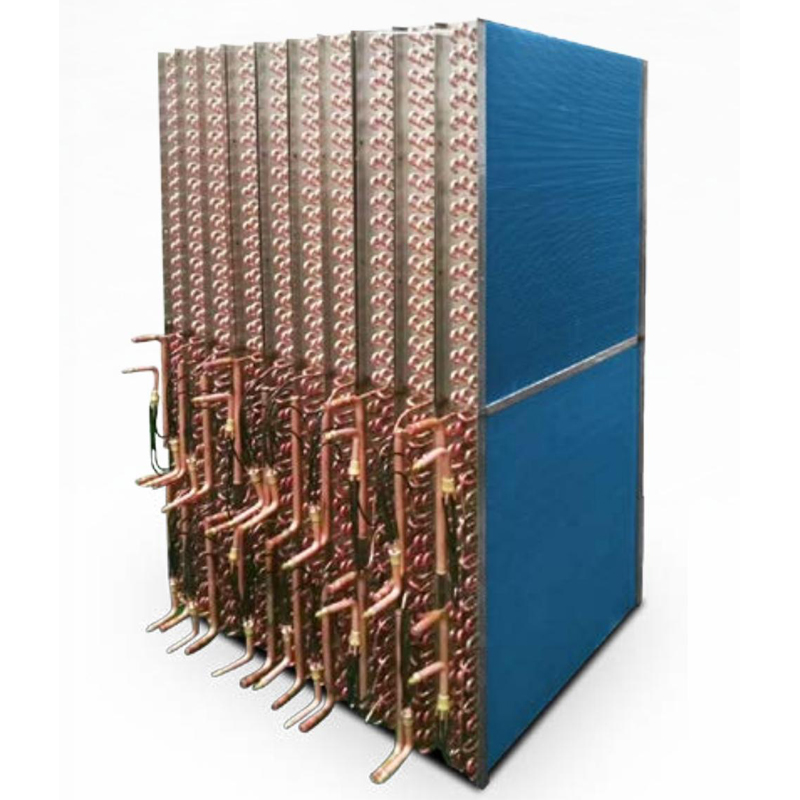

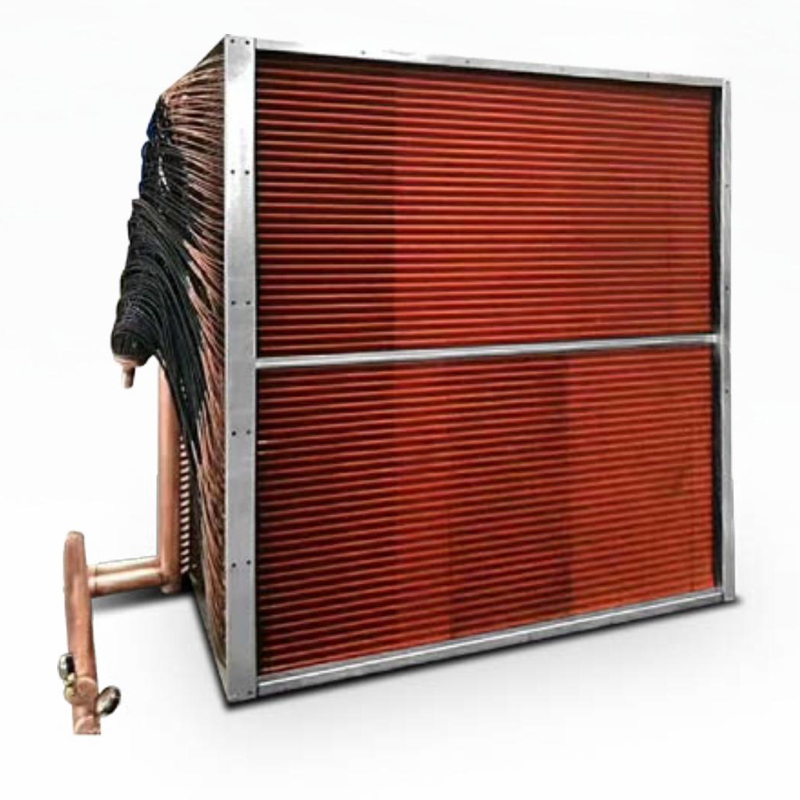

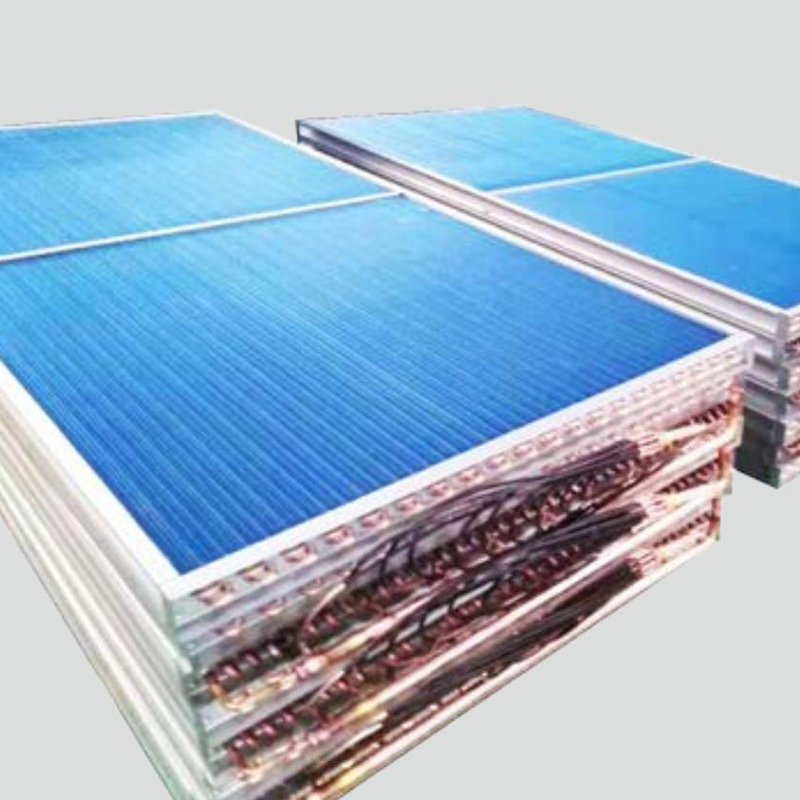

Above, high-quality copper pipes(or stainless steel pipes) are precisely paired with aluminum chips(or stainless steel chips, copper chips). After advanced mechanical distension, the tubes are closely connected with the fins to ensure maximum heat exchange efficiency. The tubes are arranged in a staggered manner,with the sinusoidal ripple design of the fins, reducing the resistance and improving the fluidity of the fluid, thus ensuring that the evaporator has an efficient heat transfer performance. All evaporators undergo a leakage inspection after 3.5 Mpa pressure, and the above aspects can be shipped to the factory to accept customer review.

| Model | Weight (Kg) | Processing capacity (L/hr) | Power consumption (kw) | Dimensions Length × Width × Height (mm) |

| 250 | 3700 | 160-200 | 6 | 1800×3650×3500 |

| 300 | 3700 | 240-300 | 7.3 | 1870×3650×3500 |

| 500 | 5500 | 400-500 | 1 1 .8 | 2400×3650×3500 |

| 750 | 8000 | 600-750 | 17 | 3600×3650×3500 |

| 1000 | 11000 | 800-1000 | 22.6 | 4800×3650×3500 |

| 1250 | 13500 | 1000-1250 | 27.74 | 6000×3650×3500 |

| 1500 | 16000 | 1200-1500 | 36 | 7200×3650×3500 |

Reviews

There are no reviews yet.