1. Introduction

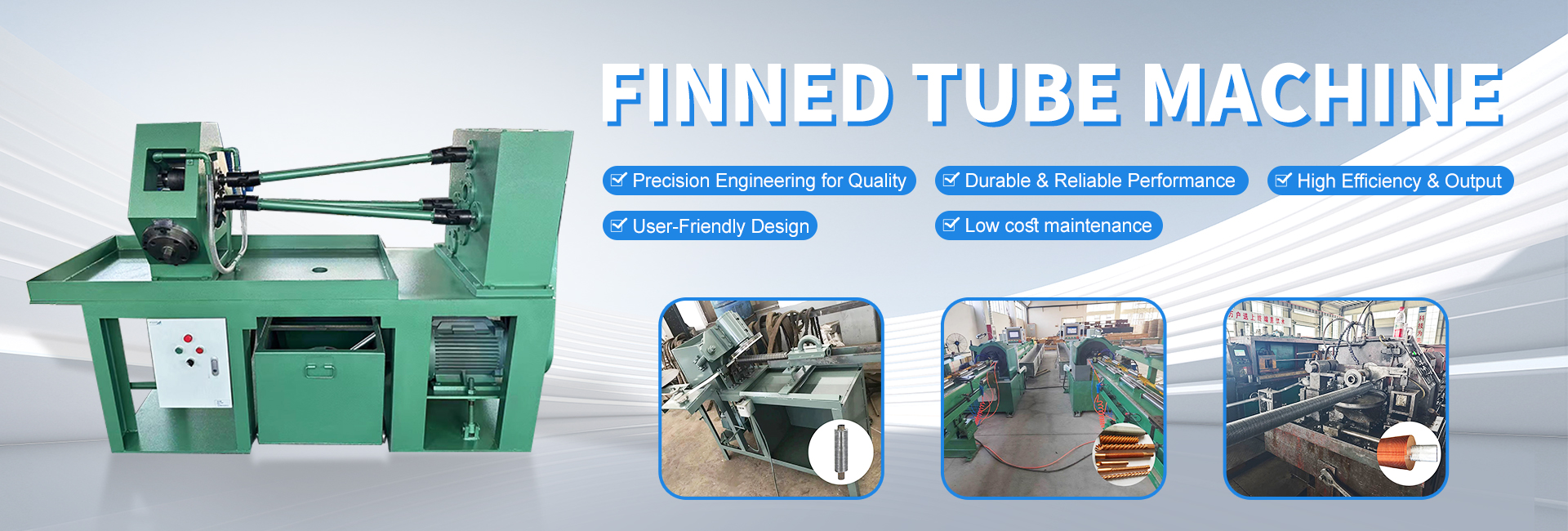

Industries nowadays have a rapidly increasing demand for efficient heat exchangers. In response, manufacturers often select extruded fin tubes for this purpose. Extruded fin tubes can provide high thermal contact and extended service life. An effective extruded fin tube machine ensures stable production performance and high-quality products for factories. Bangwin Thermal’s advanced finning technology is available at customindustrialheatexchanger.com .

2. What Is an Extruded Fin Tube

A typical extruded fin tube consists of a solid aluminum or copper sleeve.

During processing, manufacturers extrude this sleeve over a base tube to form continuous, tightly bonded fins.

Through this extrusion method, the tube gains excellent heat transfer performance and strong mechanical durability.

ASME Heat Exchanger Guidelines – https://www.asme.org/

3. Working Principle of an Extruded Fin Tube Machine

An extruded fin tube machine makes fins with a cold extrusion process. High pressure forces the aluminum over the base tube. Also, the metal flows into the fin shape without cutting or welding.

The general steps are:

- Load the base tube and aluminum sleeve.

- Position the tube inside the extrusion head.

- Start the cold extrusion system.

- Aluminum flows and forms fins.

- Measure fin height and thickness.

- Cut finished fin tubes to length.

This results in a strong metallurgical contact and good corrosion resistance.

4. Technical Details of Extruded Fin Tube Machine

A complete extruded fin tube machine line includes several coordinated components.

First, the Tube Loading Frame holds both the tube stock and the aluminum sleeves so operators can feed materials efficiently.

Next, the Extrusion Head applies high pressure to form the fins with accurate shaping.

The Fin Height Controller then keeps the fin profile consistent throughout production.

Meanwhile, a Servo Drive System moves the tube smoothly to maintain stable extrusion.

To protect the surface quality, the Cooling and Lubrication Unit dissipates heat and minimizes friction.

Finally, the Cut-to-Length System trims each finished tube precisely to its required size.

Bangwin Thermal engineers design every machine with a rigid frame and high-accuracy machining to ensure durable, long-term operation.

5. Features and Technical Benefits

An extruded fin tube machine offers a number of technical benefits for heat-exchanger manufacturers.

It has a powerful extrusion force, which ensures well-formed fins.

The processing method results in a smooth surface finish, which improves airflow and overall heat transfer.

Since the fins are tightly bonded to the base tube, the thermal conductivity is greatly enhanced.

Operators can also easily modify the fin height and geometry to suit different engineering needs.

The machine’s precision-built components also ensure uniform spacing for consistent quality.

The machine is compatible with aluminum and copper sleeves, so manufacturers can choose the most appropriate material.

The machine also maintains stable output performance, which is ideal for long production cycles.

6. Advantages of Extruded Fin Tube in Heat Exchanger Manufacturing

The use of extruded fin tube machine has some definite advantages, which include the following:

- Enhanced thermal performance:Greater metal contact and efficient heat transfer.

- Extended service life:The bonded fins do not loosen.

- Corrosion resistance:Aluminum and copper offer excellent corrosion resistance.

- Superior strength:The extruded fins are robust and have better resistance to mechanical damage.

- Reduced maintenance:The manufacturing process helps to reduce fin gaps and dust accumulation.

The reasons above account for the preference of extruded fin tubes in many industries.

7. Applications of Extruded Fin Tubes

Extruded fin tubes are used in numerous heat transfer systems, including:

* Air coolers

* Oil coolers

* Gas coolers

* Heat recovery units

* Chemical processing equipment

* HVAC systems

* Petrochemical heaters

* Power plant systems

They are used to provide reliable performance in high-corrosion and high-vibration applications.

8. Why Select Bangwin Thermal

Bangwin Thermal is the provider of stable equipment and technical assistance. We design the high quality finning machines for our partners worldwide. Fin tubes are also manufactured and heat exchanger solutions are supplied. Our website customindustrialheatexchanger.com displays machine information, drawings and technical specifications.

We offer:

* Custom design of extrusion head

* Production lines of high speed

* Guidance on installation at site

* Shipment worldwide

* Spare parts and long term service

In this way, you are assured of steady production for your factory of heat exchanger.

9. FAQ

- Why do you use an extruded fin tube machine?

It can form a strong fin bonding and higher thermal efficiency.

- What are the fin materials that can be applied to the machine?

The machine is suitable for aluminum and copper sleeve material.

- Is the machine suitable for customized fin heights?

Yes, fin height, thickness, pitch, etc. are all adjustable.

- Can the system realize high-capacity production?

Yes, Bangwin Thermal can customize high-speed lines.

- How much time does a fin tube need to produce?

It mainly depends on the length of the fin tube and the fin pitch.

10. Conclusion

The extruded fin tube machine helps factories produce a high-quality fin tube with long service life and better thermal efficiency. Because of its advantages in the production process, the extrusion process can form a fin with strong bonding force and stability. As a result, the industry can be used for a long time. Bangwin Thermal has provided many customers around the world with advanced equipment and excellent engineering service. Welcome to learn more details about the solution from customindustrialheatexchanger.com.