1. Introduction

A welded plate heat exchanger is an effective thermal solution for high pressure and high temperature systems. The fully welded plates support highly aggressive fluids with no risk of gasket failure. Industries are choosing welded plate technology for reliable heat transfer and a compact footprint. In addition, Bangwin Thermal is offering advanced welded plate systems through customindustrialheatexchanger.com for international projects with engineered solutions.

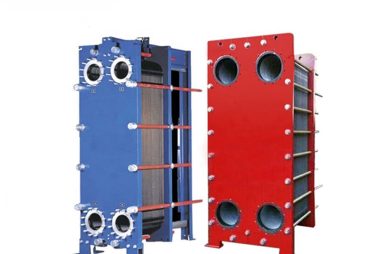

Gasketed Plate Heat Exchanger

https://customindustrialheatexchanger.com/gasketed-plate-heat-exchanger

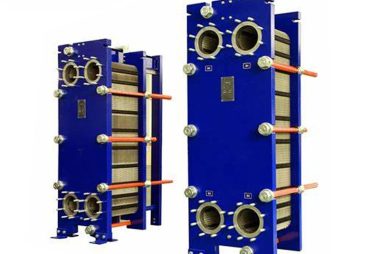

2. What Is a Welded Plate Heat Exchanger

A welded plate heat exchanger consists of metal plates that are welded together to create sealed fluid channels. The design eliminates gaskets, which improves chemical resistance and pressure tolerance. The structure supports compact installation while maintaining high heat transfer.Welded plate designs can handle corrosive media, toxic liquids, and high-temperature gas streams. In these conditions, gasketed plates may fail, but welded alternatives are more durable. In addition, the unit is capable of supporting both single-pass and multi-pass configurations.

ASME Heat Exchanger Design Standards https://www.asme.org

3. How a Welded Plate Heat Exchanger Works

Engineers arrange the thin corrugated plates in alternating channels to form the heat exchanger. Fluid one enters its channel and flows through the plate pattern first. Fluid two enters a separate sealed channel on the other side of the unit. The fluids transfer heat across the metal plate due to the temperature difference. The corrugation pattern maximizes turbulence, which improves heat transfer. The welded edges prevent leakage, and operators can run the unit safely under extreme conditions.

4. Common Characteristics of New Welded Plate Design

The following are new features that promote the stable operation of welded plate heat exchangers.

- Manufacturers weld the entire structure, eliminating gasket failure concerns.

- The machine occupies only a small area.

- Enhanced heat transfer due to the high turbulence state in the plate channel.

- Engineers can select corrosion-resistant materials for severe media.

- The design offers multiple passes for custom flow patterns.

- Easy cleaning is an option that helps reduce maintenance downtime.

On the other hand, the plate-type design is also thermally more efficient than the shell-and-tube type in many cases.

5. Types of Welded Plate Heat Exchanger

There are several types of welded plate heat exchangers depending on their application.

5.1 Fully Welded Plate Heat Exchanger

Manufacturers weld this type completely on all sides. The temperature and pressure are higher than those of the gasket type.

5.2 Semi-Welded Plate Heat Exchanger

Engineers place a gasket on one side and weld the opposite side. This type is used for refrigerants and lower pressure processes.

5.3 Plate and Shell Heat Exchanger

Manufacturers install welded plates inside a shell to form this heat exchanger. It provides high thermal efficiency and mechanical strength.

Each type is applied to various industrial fields, so the selection is based on the fluid and the degree of temperature and pressure.

6. Main Elements

The main structural elements of a welded plate heat exchanger are:

- Pack of Plates: A stack of corrugated metal plates welded together to form flow passages.

- Nozzles: Process fluid lines connected to the plates.

- Shell or Frame: Structure that holds the welded pack in place.

- Distribution Zone: Area that evenly distributes the fluid on the plates.

- Edge Sealing: Reinforced edges that maintain the mechanical strength of the assembly under pressure.

With these robust components, operators can maintain stable operation even under demanding conditions.

7. Benefits of Welded Plate Heat Exchangers

Welded plate heat exchangers offer several benefits that make them particularly suitable for industrial applications:

- High thermal efficiency is due to the corrugated plates.

- The space-saving design enables compact construction.

- Good pressure and temperature resistance.

- Suitable for use with aggressive and toxic media.

- Low maintenance, as there are no gaskets that can fail.

- Less fouling if you use turbulence-promoting patterns.

- Energy efficiency due to the high heat transfer coefficient.

Due to the robustness of the welded plates even under extreme conditions, welded plate heat exchangers are widely used in heavy industries.

8. Industrial Applications

A welded plate heat exchanger can work in many demanding service conditions:

- Chemical

- Oil & Gas

- Petrochemical

- Power

- HVAC

- Food and Beverage

- Industrial Waste Heat Recovery

- Pharmaceutical

In addition, the small size allows skid-mounted and containerized process equipment.

9. Why Bangwin Thermal

Bangwin Thermal provides high-quality welded plate heat exchangers at https://customindustrialheatexchanger.com/

We offer customer assistance in the following areas:

- Engineering-grade customization

- Premium stainless and alloys

- Strict welding QC

- Professional thermal design

- Factory-direct cost

- Rapid production and worldwide service

Thus, our heat exchangers are trusted by businesses that need dependable heat transfer.

10. FAQ

- What kind of material is used in welded plate heat exchangers?

Typically they are constructed of SS304, SS316L, titanium, and nickel alloys.

- Are welded plates suitable for corrosive fluids?

Yes, they are ideal for aggressive chemicals as there are no gaskets to wear out.

- Is maintenance easy with welded plates?

Yes, though the unit is welded together, the cleaning nozzles and backflushing is still easy.

- Where is this heat exchanger type most effective?

It is best at high-pressure, high-temperature process industries.

- Does Bangwin Thermal offer custom welded plate designs?

Yes, we customize the plate type, thickness, flow arrangement, and material grades.