Índice

- Introdução

- O que é um Tubo de aletas em espiral?

- Manufacturing Process

- Caraterísticas principais

- Technical Specifications

- Vantagens

- Aplicações industriais

- Perguntas frequentes (FAQ)

- Conclusão

Introdução

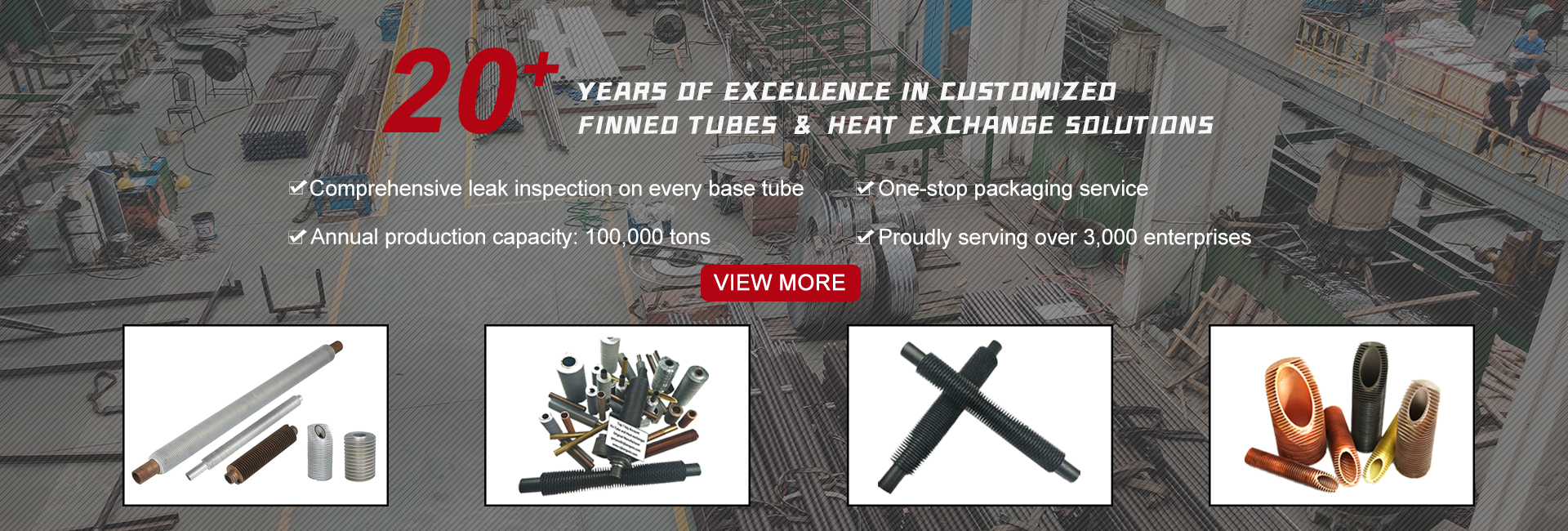

A tubo de aletas em espiral, or spiral finned tube, is a compact heat exchanger component designed to enhance the surface area for heat transfer while maintaining a small form factor. The fins are formed by wrapping a metal fin strip in a spiral shape around the tube, creating a high-efficiency heat exchanger tube with excellent mechanical strength and service life even in aggressive environments.

O tubo de aletas em espiral is a popular choice in power generation, petrochemical industry, HVAC systems, and waste heat recovery.

O que é um Tubo de aletas em espiral?

O tubo de aletas em espiral is a metal tube with continuous spiral fins on its outer surface. The finning increases the external surface area for more efficient heat transfer from the air or gas to the tube.

Main components:

- Base tube: carbon steel tube, stainless steel tube, copper tube, titanium tube, alloy steel tube, etc.

- Fin: aluminum fin, copper fin, stainless steel fin, carbon steel fin, etc.

- Fin type: L-fin, KL-fin, G-fin, and welded spiral fin.

The unique spiral structure provides uniform heat distribution and better performance under thermal stress and vibration.

Manufacturing Process

- The main steps to produce a tubo de aletas em espiral are tube preparation, fin forming, spiral winding, bonding, finishing, and testing.

- Tube preparation: The base tube is cleaned and straightened.

- Fin forming: The metal fin strip is formed and prepared for the winding process.

- Spiral winding: The fin strip is wound in a spiral direction around the tube under high tension.

- Bonding: The fin is either L-shaped, KL-shaped, G-shaped, or welded to the tube.

- Finishing & testing: The final tubo de aletas em espiralis inspected for fin tightness, uniformity, and dimensions.

Caraterísticas principais

- Enhanced heat transfer surface area for high performance.

- Durable fin-to-tube bond for long service life.

- Corrosion & high temperature/pressure resistance.

- Aluminum, copper, stainless steel, and carbon steel materials.

- Easy to install and maintain.

- Customizable fin dimensions and shapes.

Technical Specifications

Parameter | Especificação |

Tube Outer Diameter | 19 mm – 63 mm |

Altura da barbatana | 6 mm – 20 mm |

Espessura da barbatana | 0.3 mm – 1.2 mm |

Passo da barbatana | 8 – 11 FPI (fins per inch) |

Material da barbatana | Aluminum, Copper, Carbon Steel, Stainless Steel |

Material do tubo | Carbon Steel, Stainless Steel, Alloy Steel |

Max Operating Temperature | Up to 450 °C |

Vantagens

- High Heat Transfer Efficiency: The spiral fin provides the largest surface area between the air/gas and the tube.

- Durable Structure: The winding method forms a strong fin bond to the tube.

- Versatile Applications: Used for both heating and cooling process.

- Corrosion & Temperature Resistant: Can work in corrosive and high-temperature/pressure environments.

- Cost-Effective: Long service life and easy maintenance save operating cost.

- Flexible Design: Multiple fin types (L, KL, G, welded) for various thermal performance needs.

Aplicações industriais

- Power Generation: Boiler economizers, air preheaters, etc.

- Petrochemical Industry: Process heaters, coolers, etc.

- HVAC Systems: Condensers, evaporators, air handling units.

- Food & Beverage Industry: Heat recovery, thermal processing.

- Oil & Gas: Gas coolers, refinery equipment.

- Waste Heat Recovery: Industrial heat recovery from exhaust.

Perguntas frequentes (FAQ)

Q1: What is the difference between spiral fin tubes and extruded fin tubes?

A1: Tubo de aletas em espirals are manufactured by wrapping a fin strip around the tube, whereas extruded fin tubes are made by extrusion method. Tubo de aletas em espirals are generally more cost-effective and suitable for a wider range of applications.

Q2: Can spiral fin tubes handle high temperatures?

A2: Yes, based on the fin and tube material, it can handle high temperatures of up to 450 °C.

Q3: Are spiral fin tubes corrosion-resistant?

A3: Yes, especially when using aluminum or stainless steel fins.

Q4: In which industries are spiral fin tubes most commonly used?

A4: Power plants, chemical industry, HVAC systems, oil & gas, and food processing are some of the most common industries that use tubo de aletas em espirals.

Q5: Can the size and pitch of fins be customized?

A5: Yes, all the dimensions including tube OD, fin height, thickness, and pitch can be customized to your project requirements.

Conclusão

A tubo de aletas em espiral is an excellent, high-quality, efficient, and cost-effective heat exchanger tube solution for modern applications. The spiral design increases the heat transfer area, reduces energy consumption, and provides long-lasting reliable performance in harsh environments.

Choose either standard or custom-engineered tubo de aletas em espirals for your power generation, HVAC, oil & gas, industrial heat recovery, or any other heat exchanger application.