Introdução do produto:

- As caldeiras de óleo térmico a carvão (biomassa) utilizam carvão ou biomassa como fonte de energia e óleo térmico como meio de transferência de calor. Eles podem servir como fontes de calor de alta temperatura para vários ambientes abaixo de 350 ℃ e são amplamente utilizados em várias indústrias que requerem aquecimento ou secagem a alta temperatura. Este produto apresenta alta temperatura, baixa pressão, controle preciso da temperatura e alta utilização de energia térmica. Um gerador de vapor também pode ser selecionado para produzir vapor saturado abaixo de 1.3MPa para uso do utilizador.

- Seleção de combustível: Carvão, Biomassa, Semi-coque

- Meio de transferência de calor: Óleo térmico, máximo 320℃

Caraterísticas do produto:

- Atinge uma elevada eficiência de funcionamento a pressões de funcionamento relativamente baixas, possuindo caraterísticas técnicas de baixa pressão e alta temperatura, permitindo um aquecimento estável e uma regulação precisa da temperatura para satisfazer diversos requisitos.

- Possui dispositivos completos de controlo de funcionamento e de monitorização da segurança, garantindo um funcionamento conveniente e uma segurança fiável.

- Circulação em circuito fechado, transferência de calor em fase líquida, baixa perda de calor, efeito significativo de poupança de energia e baixos custos de funcionamento.

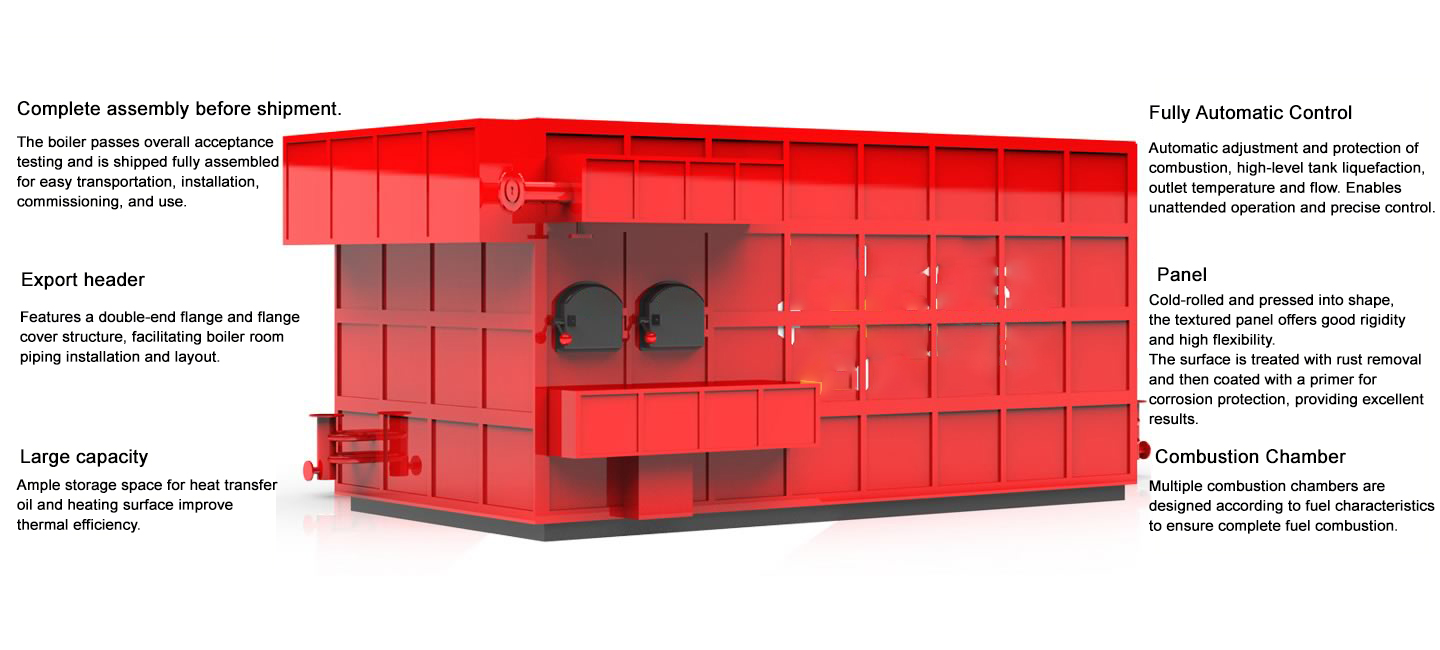

- Montagem rápida ou pré-montada para um transporte cómodo, um período de instalação curto e uma entrada em funcionamento rápida.

- Estrutura compacta, tudo pode ser organizado num único andar, poupando no investimento da sala da caldeira.

- A caldeira tem um bom isolamento, utilizando materiais de isolamento de alta eficiência e tecnologia de construção avançada, resultando numa perda mínima de calor das paredes da fornalha.

Princípio de funcionamento:

A caldeira transportadora de calor orgânico da série YGL usa uma bomba de circulação de alta temperatura para forçar o óleo de transferência de calor em um processo de circulação de circuito fechado, fornecendo energia térmica para o equipamento que usa calor e, em seguida, devolvendo-o à caldeira para reaquecimento. Por ter as vantagens de alta temperatura (acima de 320 ℃) e baixa pressão (0,3-0,5MPa), e sua temperatura de aquecimento pode ser controlada com precisão, pode substituir a caldeira a vapor original para aquecimento. Ao mesmo tempo, este equipamento não requer equipamento de tratamento de água e elimina as perdas de calor causadas por fugas e derrames associados às caldeiras a vapor. Por conseguinte, tem um baixo investimento inicial e baixos custos de funcionamento, o que o torna um dispositivo de aquecimento seguro, eficiente e económico em termos energéticos.

| Tabela de parâmetros do forno de transporte de calor orgânico da série montada em skid | |||||||

| Capacidade de aquecimento: 10 kcal/h | 30 | 60 | 80 | 100 | 120 | 160 | |

| Potência nominal (MW) | 0.35 | 0.7 | 0.95 | 1.2 | 1.4 | 1.9 | |

| Pressão nominal de trabalho | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | |

| Temperatura nominal de saída (MPa) | 300°C | 300°C | 300°C | 300°C | 300°C | 300°C | |

| Capacidade do óleo | 0.237 | 0.64 | 0.7 | 0.92 | 1.07 | 1.58 | |

| Caudal de circulação (m³/h) | 28.354 | 56.7 | 76.96 | 97.2 | 118.46 | 153.9 | |

| Diâmetro da ligação da tubagem (DN) | 80 | 100 | 100 | 125 | 125 | 150 | |

| Modelo do quadro elétrico de controlo | DK-350 | DK-700 | DK-950 | DK-1200 | DK-1400 | DK-1900 | |

| Capacidade instalada (KW) | 10 | 20 | 25 | 30 | 30 | 45 | |

| Dimensões exteriores (transporte) | Comprimento (mm) | 6980 | 7680 | 8150 | 8650 | 9080 | 9880 |

| Largura (mm) | 2650 | 2850 | 2950 | 3050 | 3050 | 3100 | |

| Altura (mm) | 2650 | 3050 | 3660 | 3660 | 3660 | 3680 | |

| Peso máximo de transporte (T) | 5 | 8.26 | 9.68 | 10.94 | 11.63 | 13.42 | |

Avaliações

Ainda não existem avaliações.