Fin Tube Machine Manufacturer: The Perfect Partner for Heat Exchanger Equipment

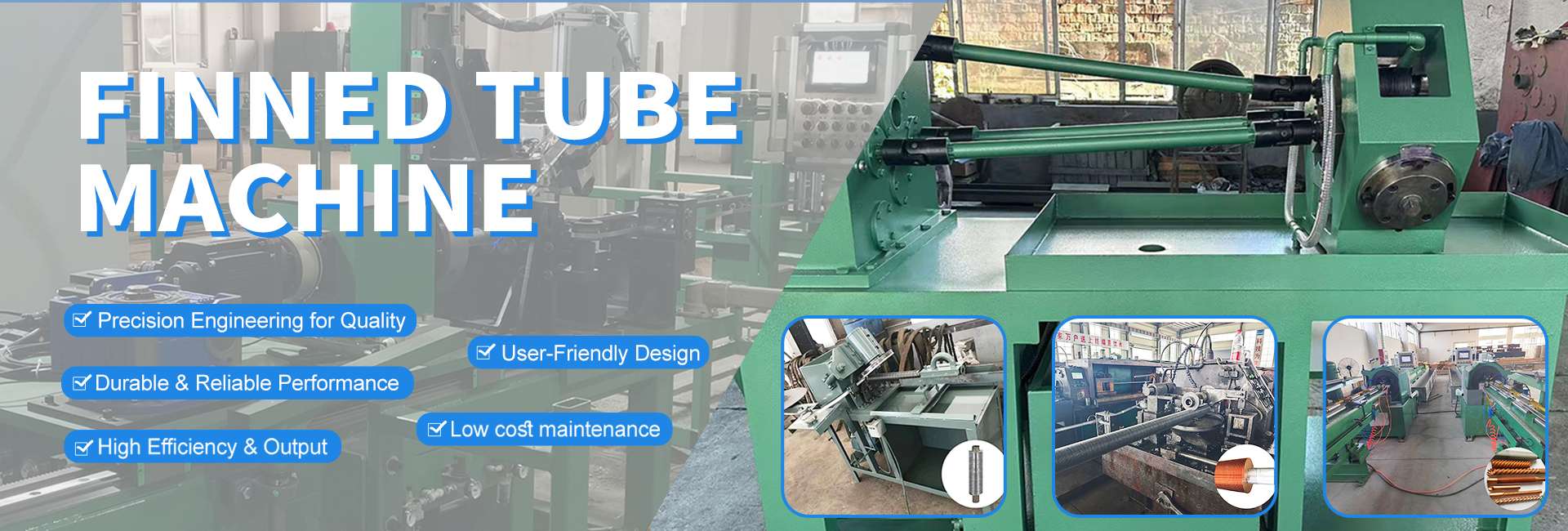

A fin tube machine manufacturer offers a range of equipment for creating finned tubes used in heat exchangers.

These machines enhance thermal efficiency and aid in energy conservation.

Equipped with precision engineering and innovative technology, these fin tube machines offer consistent quality and extended lifespan.

In today’s industrial landscape, the demand for efficient heat transfer is on the rise.

Consequently, having reliable equipment is of paramount importance.

Thus, selecting a reputable fin tube machine manufacturer ensures enhanced productivity and long-term value.

Fin Tube Machine Manufacturer: Guide, Types, Features, and Applications

Fin tube machines are used in producing finned tubes for various heat exchange applications. This article will provide a brief introduction to fin tube machines, their types, features, manufacturers, and how these machines are used in different industries.

1. What Is a Fin Tube Machine

Fin tube machine means a device that can produce finned tubes. The fins are extended surfaces made of metal to increase the surface area and enhance heat transfer efficiency. Fin tubes are commonly used in boilers, condensers, evaporators, air coolers, and other heat exchangers.

Fin tube machine manufacturer refers to the company that designs, engineers, and manufactures fin tube forming systems for different industries. They produce fin tube machines to work with various materials like carbon steel, stainless steel, copper, aluminum, etc. The manufacturer ensures each system is accurate, durable, and easy to operate.

Learn more about finned tube heat transfer at the astm.org

2. Types of Fin Tube Machines

There are different types of fin tube machines in the market. They mainly vary in terms of finning method and fin tube forming processes. Here are the commonly used fin tube machines:

- Extruded Fin Tube Machine:It forms fins by extruding aluminum material around the base tube.

- High-Frequency Welding Fin Tube Machine:It welds steel fins to the tube by using a high-frequency current.

- L Type Fin Tube Machine:It tightly wraps L-shaped fins around the tube.

- G Type Fin Tube Machine: It inserts the fin root inside the tube surface and bonds strongly.

- Low Fin Tube Machine:It makes low-profile fins that are compact and space-saving.

- Spiral Fin Tube Machine:It produces spiral fins that increase turbulence and heat transfer.

Moreover, many fin tube machine manufacturers also offer automatic control systems and digital readouts to ensure precise and efficient production.

Discover our High-Frequency Welding Fin Tube Machine for efficient heat exchanger tube production.

3. Key Components and Features

In addition, a fin tube machine manufacturer should have several key components and features in each system. They include:

- Main Frame:It supports the machine’s structure and ensures stability and precision.

- Tube Feeding System:It supplies the base tube and fin material to the forming unit.

- Fin Forming Unit:It shapes and attaches the fins to the base tube.

- Welding or Rolling System:It bonds the fins to the tube either by welding or rolling.

- Cooling System: It cools down the machine and prevents overheating during production.

- PLC Control Panel:It monitors the machine’s speed, tension, and temperature in real time.

In addition, modern fin tube machines also support features such as automatic lubrication, adjustable fin pitch, high-speed operation, etc. These enhance the machine’s efficiency, reliability, and uniform fin quality.

4. Advantages of Choosing a Reliable Manufacturer

Choosing a fin tube machine from a professional manufacturer has many benefits. They include:

- Precision:Professional machines use advanced CNC control systems to ensure precise and consistent fin spacing.

- Durability:Machines from reputable manufacturers are made of heavy-duty materials and have a stable and robust frame.

- Customization: You can customize the machine according to different tube sizes, fin shapes, and materials.

- Efficiency:Automation features and fast speed reduce manual labor and increase production.

- Technical Support:Professional manufacturers have skilled technical teams to offer on-site training and after-sales service.

- Global Service:Manufacturers can ship their machines worldwide and provide installation and commissioning support.

Furthermore, a trusted supplier also offers spare parts and long-term maintenance support.

5. Applications of Fin Tube Machines

Fin tube machines have various applications in different industries. They include:

- Power Plants:Producing finned tubes for boilers, condensers, economizers, etc.

- Chemical Industry:Making finned tubes for process heat recovery and cooling applications.

- HVAC Systems:Producing finned tubes for air conditioners, chillers, and heat pumps.

- Oil and Gas:Manufacturing finned tubes for gas coolers, heat recovery units, and exchangers.

- Refrigeration Systems:Producing finned tubes for evaporators, condensers, and heat exchangers.

- Energias renováveis:Making finned tubes for solar collectors, geothermal heat exchangers, etc.

Because of the widespread applications, fin tube machines are becoming increasingly important in the modern heat transfer industry.

6. Production Process

The fin tube production process includes the following steps:

- Load the base tube and fin material into the machine.

- Adjust the fin pitch, height, and tension according to the specifications.

- Start the machine and watch it forming or welding the fins.

- Inspect the fin bonding and alignment to ensure quality.

- Cut the finned tube to the required length and perform quality checks.

- Pack the finished tubes into boxes or cartons for storage or delivery.

In addition, many modern fin tube machines also use servo motors for better speed control and energy saving.

7. Frequently Asked Questions (FAQ)

Q1: What materials can the fin tube machine process?

A: Carbon steel, stainless steel, copper, aluminum

Q2: What is the normal working speed?

A: According to different models, the speed is 1-10 meters/minute.

Q3: Can it produce various types of fins?

A: Yes. Fin tube machine manufacturers produce extruded, welded, and wrapped fins.

Q4: Is operator training available?

A: The professional manufacturers have the operator’s training and installation services.

Q5: What is the lifespan of a fin tube machine?

A: With proper maintenance and care, it can last more than 10 years while maintaining a high-efficiency level.

8. Conclusion

To sum up, a fin tube machine manufacturer is an important piece of equipment that can help produce high-quality fin tubes for heat exchangers.

Fin tube machine manufacturers can provide industries with energy-efficient and cost-effective solutions to improve their productivity and performance.

In addition, they can also ensure the precision, consistency, and durability of each machine through their expertise and experience.

Therefore, choosing a reliable and professional fin tube machine manufacturer can ensure that you get the best quality products and long-term service.

Fin tube machines are widely used in various industries, such as power generation, HVAC, chemical, and others, and will continue to play a crucial role in modern thermal systems.