Product Introduction:

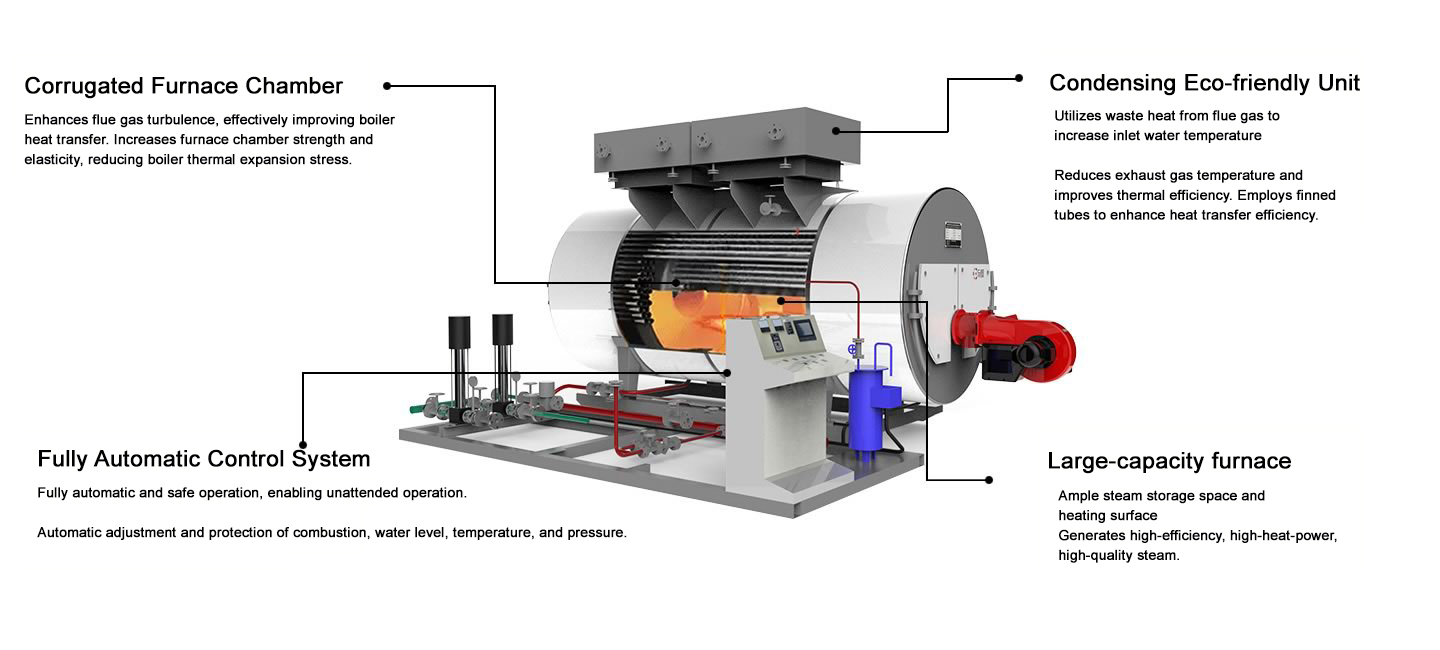

The WNS series low-NOx condensing boiler is a fully automatic, horizontal, internal combustion, low-NOx condensing, quick-installation oil (gas) boiler. The boiler body adopts a wet-back two-pass structure: the corrugated furnace and combustion chamber constitute the first pass, and the threaded flue tubes form the second pass. The economizer and condenser are located at the top of the boiler, forming the third pass for flue gas outside the furnace.

Performance Characteristics:

- High Efficiency and Energy Saving. The economizer and condenser have large heat exchange areas and a high condensation rate of water vapor in the flue gas, fully absorbing the heat released by the condensation of water vapor in the flue gas, achieving a thermal efficiency of over 99%. The use of threaded flue tubes for convective heating effectively improves the boiler’s heat transfer efficiency.

- Good Environmental Performance. Harmful components such as CO2, NOx, and SO2 in the flue gas dissolve in the condensate, effectively reducing atmospheric pollutant emissions. Simultaneously, the large-size furnace structure and flue gas recirculation technology enable ultra-low NOx emissions for gas-fired boilers, with NOx emissions ≤30mg/Nm3, fully complying with increasingly stringent national environmental protection requirements.

- The spiral finned tubes and shell of the economizer and condenser are made of ND steel resistant to sulfuric acid corrosion, greatly extending the equipment’s service life. The combination of intelligent combustion control and a fully automatic safety interlock protection system ensures economical, environmentally friendly, and safe operation.

Working Principle:

In boiler flue gas heat loss, besides the sensible heat, water vapor also carries away a significant amount of latent heat of vaporization. If the flue gas temperature is lowered, allowing all or part of the water vapor in the flue gas to condense, and the latent heat released during condensation to be recovered and utilized, the boiler’s effective heat utilization increases, significantly improving its thermal efficiency.

The WNS type low-NOx condensing gas-fired boiler addresses key technical factors such as the relationship between the condensation rate of water vapor in the flue gas and the flue gas temperature, the relationship between the condensation rate and thermal efficiency, and the corrosion rate of condensate on different steel grades. Through rational design of the heating surface, it lowers the flue gas temperature, ensuring that the water vapor in the flue gas reaches the designed condensation rate, thus greatly improving the boiler’s thermal efficiency.

| Rated Evaporation Capacity | t/h | 0.5 | 1 | 2 | 3 | 4 | 6 | 8 | 10 | 15 | 20 |

| Rated Steam Pressure | MPa | (0.4)0.7 | (0.7)(1.0)1.25 | (1.0)1.25(1.6) | (1.0)1.25(1.6) | (1.0)1.25(1.6) | (1.0)1.25(1.6) | (1.0)1.25(1.6) | (1.0)1.25(1.6) | 1.25(1.6) | 1.25(1.6) |

| Rated Steam Temperature | ℃ | (151)170 | (170)(184)193 | (184)193(204) | (184)193(20) | (184)193(204) | (184)193(204) | (184)193(20) | (184)193(20) | 193 (204) | 193 (204) |

| Rated Feedwater Temperature | ℃ | 20 | 20 | 20 | 20 | 20 | 20(105) | 20(105) | 20(105) | 20(105) | 20(105) |

| Calculated Heat Exchange Area | m² | 21.5 | 37.2 | 99.6 | 135 | 200.4 | 265 | 357 | 409 | 582 | 762 |

| Design Thermal Efficiency (Oil/Gas) | % | 93.34/93.7 | 95.39/96.01 | 98.47/99.7 | 98.1/99.5 | 98.23/99.9 | 97.6/98.48 | 98.64/99.59 | 98.3/99.27 | 98.45/99.9 | 98.2/99.4 |

| Maximum Transport Weight of Boiler Components | 3.4 | 4.6 | 8.5 | 10.5 | 13 | 20 | 22 | 25.5 | 38 | 51 | |

| Boiler Water Capacity | t | 1.48 | 2.5 | 5.6 | 5.8 | 8.5 | 11.8 | 14.2 | 15.2 | 24.3 | 35.9 |

| Combustion Method | Micro-positive pressure combustion chamber | ||||||||||

| Combustion Control Method | Fully automatic adjustment | ||||||||||

| Applicable Fuel | Light diesel/natural gas | ||||||||||

Ulasan

Belum ada ulasan.