Basics of Gasketed Plate Heat Exchanger

Gasketed plate heat exchanger provides excellent thermal performance in many cooling and heating applications. The unit consists of several metal plates and gaskets to form individual channels for two fluids. Due to this structure, the exchanger allows rapid heat transfer and straightforward maintenance. For this reason, industries now select it for its flexibility, efficiency, and long-term value.

At Nanjing Bangwin Thermal, we offer industrial heat exchanger solutions and expert engineering knowledge on our website, customindustrialheatexchanger.com. Therefore, this guide aims to help buyers and engineers better understand a gasketed plate heat exchanger, its working principles, and the selection.

Learn more about industrial heat exchanger solutions here: https://customindustrialheatexchanger.com/

Gasketed Plate Heat Exchanger (GPHE) Explained

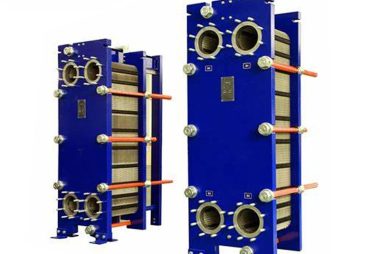

comprises thin metal plates and gaskets around the edges. The plates form a series of parallel channels where the fluids flow in alternate paths. As a result, the hot fluid transfers heat to the cold fluid through the plates.

The separated plates of the two fluids prevent any mixing of the media. Also, the gasketed design allows quick disassembly for easy cleaning. Engineers commonly use this design in systems that need regular maintenance or flexible capacity.

Structure and Working Principle of a Gasketed Plate Heat Exchanger

General heat exchanger standards: https://www.ashrae.org/ (ASHRAE)

Main Features

✔ High Heat Transfer Efficiency

The larger plate surface allows for faster heat transfer. Thus, it takes more duty for its small body.

✔ Easy Maintenance

The frame disassembles within minutes, allowing quick cleaning or plate replacement with basic tools.

✔ Flexible Configuration

You can add or remove plates according to needs. Therefore, it easily optimizes capacity for new conditions.

✔ Leak-Free Operation

High-quality gaskets route the fluid flow. It also prevents leakage at normal operating pressure.

✔ Wide Temperature and Pressure Range

Engineers use this equipment in HVAC systems, food processing, chemical and power industries.

Working Principle

The working principle consists of several steps:

Fluids enter separate inlets and move through alternate channels formed by the plates, which promote rapid heat transfer through their thin metal structure.

In addition, the gasket pattern routes the flow in a specific pattern, which increases turbulence and improves performance.

Benefits

1. Good Thermal Performance

The corrugated structure results in turbulence. Heat transfer is faster as a result.

2. Low Operating Cost

Less energy is consumed but more powerful operation is obtained.

3. Easy Expansion

Addition of plates is easier. In this way, the system can be expanded with the growth of the production.

4. Compact Structure

Its compact footprint helps factories save valuable floor space.

5. Fast Cleaning

The gasketed structure allows the exchanger to be disassembled faster.

6. Long Service Life

Stainless steel or titanium plates used in the system make it resistant to corrosion.

Use of Gasketed Plate Heat Exchanger

The Products can be found in many industries as follows:

- HVAC heating or cooling

- Chiller systems

- Chemical industry

- Dairy and food production

- Pharmaceutical industry

- Marine cooling system

- Power station

- Oil and gas

For many industries, it is preferred to shell and tube heat exchanger due to the easy inspection design.

How to Choose

1. Heat Duty Requirement

Provide capacity to meet the thermal load.

2. Plate Material

Stainless steel is for general application. Titanium is for corrosive fluid service.

3. Gasket Material

NBR, EPDM, and Viton are used for a variety of temperature and chemical conditions.

4. Flow Rate

Allow for stable operation with the expected flow rate.

5. Pressure Drop

A lower pressure drop across a system can provide energy savings.

6. Maintenance Frequency

Select a gasket material to support your anticipated cleaning frequency.

Additional engineering assistance is available at customindustrialheatexchanger.com.

FAQ

- How often should I replace the gaskets?

Replacement frequency for gaskets depends on operating temperature, cleaning cycles, and exposure to chemicals. A one–three-year replacement cycle is common.

- Which industries use this exchanger most?

HVAC, food, chemical, and power industries use this type of heat exchanger often.

- Can I increase plate capacity later?

you can add plates at any time.

- Is the cleaning process simple?

the frame can open easily for cleaning.

- Does this design save energy?

rapid heat transfer improves efficiency and reduces operating energy use.

Conclusion

A gasketed plate heat exchanger provides high efficiency, easy maintenance, and expandability, making it a preferred choice for long-term industrial operation. If you want industrial heat exchanger solutions, Nanjing Bangwin Thermal supplies professional engineering insights to customindustrialheatexchanger.com for buyers and engineers to consider.