Boiler

Coal-fired steam and hot water boilers;Low-NOx condensing oil (gas) boiler;Oil (gas) boilers;Vacuum hot water boiler;Waste heat boiler;YLW Series Thermal Oil Furnaces;YYQW series oil (gas) thermal oil heaters

Product Advantages

Material Advantages:

The raw materials are sourced from leading industry steel plates, ensuring stable and reliable quality. This effectively reduces the number of longitudinal and circumferential welds and end cap splicing welds. Only burrs need to be trimmed from the cylinder body, resulting in no large waste materials, improving material utilization and guaranteeing product quality.

The standard carbon steel submerged arc welding wire and flux use Lincoln welding wire and flux from the USA, ensuring stable and reliable welding quality and a beautiful appearance.

Both domestic and imported paints are available, providing an attractive appearance and good weather resistance after painting.

Processing Capabilities and Technological Advantages:

1. Laser blanking ensures high precision with an error within 0.05 mm, guaranteeing welding quality; heat exchanger baffles can be directly laser-cut.

2. For stainless steel longitudinal and circumferential welds ≤10 mm thick, plasma welding is used, with single-sided welding and double-sided forming, reducing welding wire consumption. Compared to submerged arc welding, it eliminates the need for carbon arc gouging, avoiding carburization, resulting in a beautiful appearance, low heat input, and excellent weld quality. Radiographic testing pass rate is over 99%.

3. Argon arc automatic welding machine provides high and stable welding quality and a beautiful weld appearance.

spectrometer

membrane wall production line

laser cutting machine

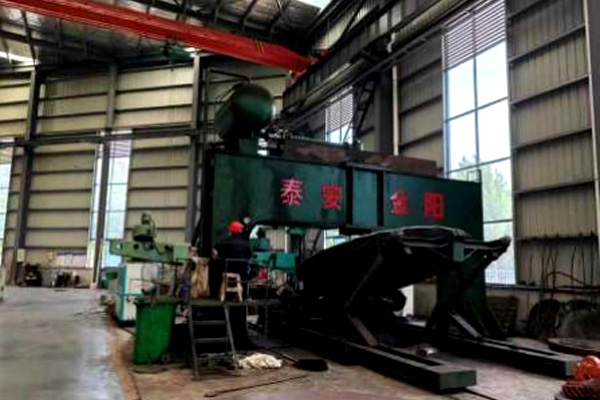

heavy duty plate rolling machine

head drumming machine

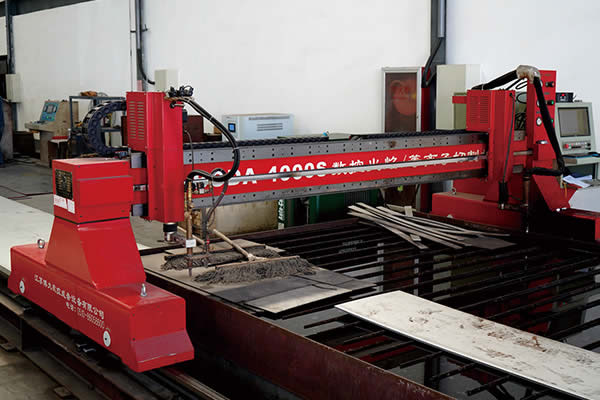

double drill bit gantry cnc drill

cnc cutting machine

chronicity removal water purifier

Advantages of a professional, assembly-line production model:

Product manufacturing is divided into more than a dozen processes, including material preparation, end cap pressing, rolling, longitudinal and circumferential seam welding, assembly welding, machining, heat treatment, hydrostatic testing, sandblasting, and painting. Each process is equipped with professional personnel, and further subdivision of tasks is carried out within each process, effectively improving work efficiency and product quality.