Product Introduction:

This boiler features a D-type layout, natural circulation, double-drum water-tube design, longitudinally arranged drums, a fully membrane-type water-cooled wall structure, and slightly positive pressure combustion. The furnace is enclosed by a membrane wall. Flue gas enters the convection tube bundle connecting the upper and lower drums from the furnace outlet. After passing through the convection tube bundle, the flue gas enters the tail heating surface—the ND steel spiral fin economizer and condenser—and finally exits into the atmosphere through the flue and chimney.

Performance Characteristics:

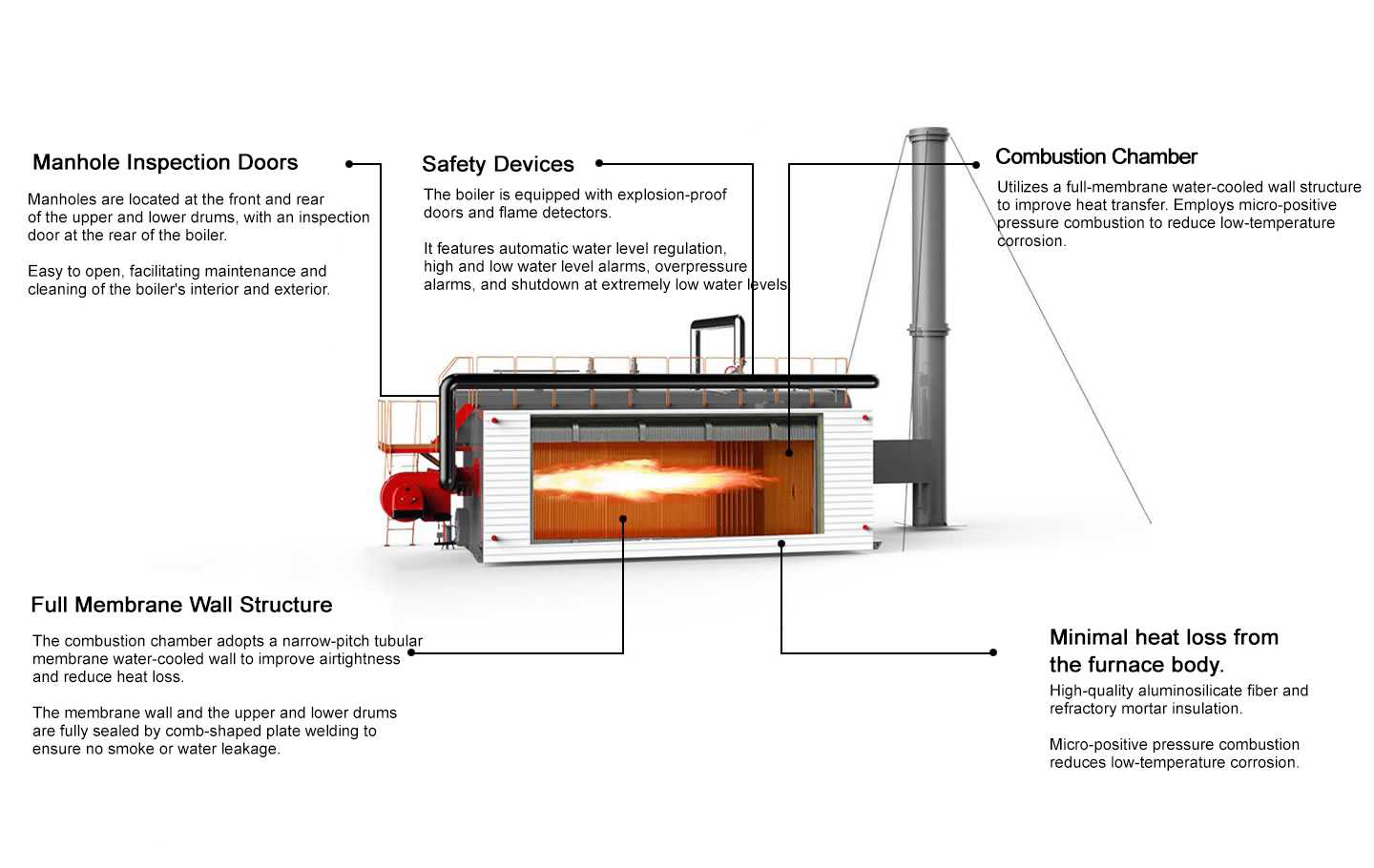

1. Full membrane wall structure, airtight design, low flue gas heat loss, and high thermal efficiency;

2. Compact structure, small installation volume, saving investment;

3. Steam boilers use natural circulation with a large cross-sectional ratio, while hot water boilers use forced circulation, ensuring safe and reliable water circulation;

4. Equipped with well-known high-efficiency burners and auxiliary equipment, achieving fully automatic operation;

5. Feedwater pump uses continuous electric regulation and has high and low water level alarm interlock protection functions;

6. The furnace is equipped with inspection holes, greatly facilitating use and maintenance, and the furnace top is equipped with an explosion-proof door.

Working Principle:

In boiler flue gas heat loss, besides the sensible heat, water vapor also carries away a significant amount of latent heat of vaporization. If the flue gas temperature is lowered, allowing all or part of the water vapor in the flue gas to condense, and the latent heat released during condensation to be recovered and utilized, the boiler’s effective heat utilization increases, significantly improving its thermal efficiency.

The WNS-type low-NOx condensing gas-fired boiler addresses key technical factors such as the relationship between the condensation rate of water vapor in flue gas and the exhaust gas temperature, the relationship between the condensation rate and thermal efficiency, and the corrosion rate of condensate on different steel grades. Through rational design of the heating surface, it reduces the exhaust gas temperature and ensures that the water vapor in the flue gas achieves the designed condensation rate, thus significantly improving the boiler’s thermal efficiency.

Due to the adoption of a large-size furnace structure and flue gas recirculation technology, ultra-low NOx emissions can be achieved for this gas-fired boiler, with NOx emissions ≤30mg/Nm3.

| Boiler Model/Project | SZS10 | SZS15 | SZS20 | SZS25 | SZS30 | SZS35 | SZS40 | ||

| Rated Evaporation Capacity | t/h | 10 | 15 | 20 | 25 | 30 | 35 | 40 | |

| Rated Steam Pressure | MPa | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | 1.25/1.6 | |

| Rated Steam Temperature | ℃ | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | 194/204 | |

| Rated Feedwater Temperature | ℃ | 20(104) | 20(104) | 104 | 104 | 104 | 104 | 104 | |

| Calculated Heat Exchange Area | m2 | 357.7 | 524 | 702.5 | 805.2 | 905.2 | 1052 | 1208 | |

| Design Thermal Efficiency (Oil/Gas) | % | 98.48/99.35 | 98.4/99.3 | 98.34/99.15 | 98.1/99.48 | 98.2/99.2 | 98.6/99.4 | 98.64/99.5 | |

| Maximum Transport Weight of Boiler Components | t | 30 | 40 | 46.3 | 52 | 55.7 | 68 | 76 | |

| Boiler Water Capacity | t | 10.1 | 14.7 | 16.9 | 18.9 | 21.6 | 23.8 | 27.7 | |

| Combustion Method | Combustion chamber | ||||||||

| Combustion Control Method | Fully automatic proportional control | ||||||||

| Applicable Fuel | Natural gas, light diesel oil, coke oven gas | ||||||||

| Fuel Consumption | Natural gas | Nm3/h | 805 | 1195 | 1600.7 | 1972 | 2190 | 3060 | 3060 |

| Light diesel | Kg/h | 663 | 986 | 1319.1 | 1598 | 1860 | 2540 | 2540 | |

| Alimentation électrique | 380V/50Hz | ||||||||

| Water Pump | Electric power | KW | 15 | 15 | 18.5 | 30 | 37 | 45 | 45 |

| Circulating Water Pump | Electric power | KW | 1.5 | 1.5 | 3 | 3 | 3 | 4.5 | 4.5 |

| Fan | Electric power | KW | 22 | 30 | 45 | 75 | 90 | 110 | 110 |

| Maximum shipment dimensions | mm | 7490×2790 | 9120×3375 | 10050×3330 | 10200×3800 | 10000×4030 | 11000×4300 | 12000×4300 | |

| ×3516 | ×3566 | ×4066 | ×4150 | ×4230 | ×4230 | ×4530 | |||

Avis

Il n’y a pas encore d’avis.