Table des matières

- Introduction

- What is a Laser Welding Fin Tube Machine?

- Description du produit

- Caractéristiques principales

- Détails techniques

- Avantages

- Applications

- FAQ

1. Introduction

Les Machine à souder les ailettes au laser is the newest welding equipment used for the production of finned tubes. Finned tubes are a common component in heat exchangers, and laser welding provides a strong bond, little thermal stress, and high efficiency to ensure high performance for advanced heat exchanger applications.

2. What is a Laser Welding Fin Tube Machine?

A Machine à souder les ailettes au laser is an industrial welding machine that bonds fins to the base tube using focused and high-intensity laser energy. Laser welding is an improved technology of the traditional high-frequency welding for fins. The former provides a deeper, cleaner, and stronger weld with less material distortion compared to the latter. This allows for a stronger bond between fins and the tube that is highly durable and long-lasting.

3. Description du produit

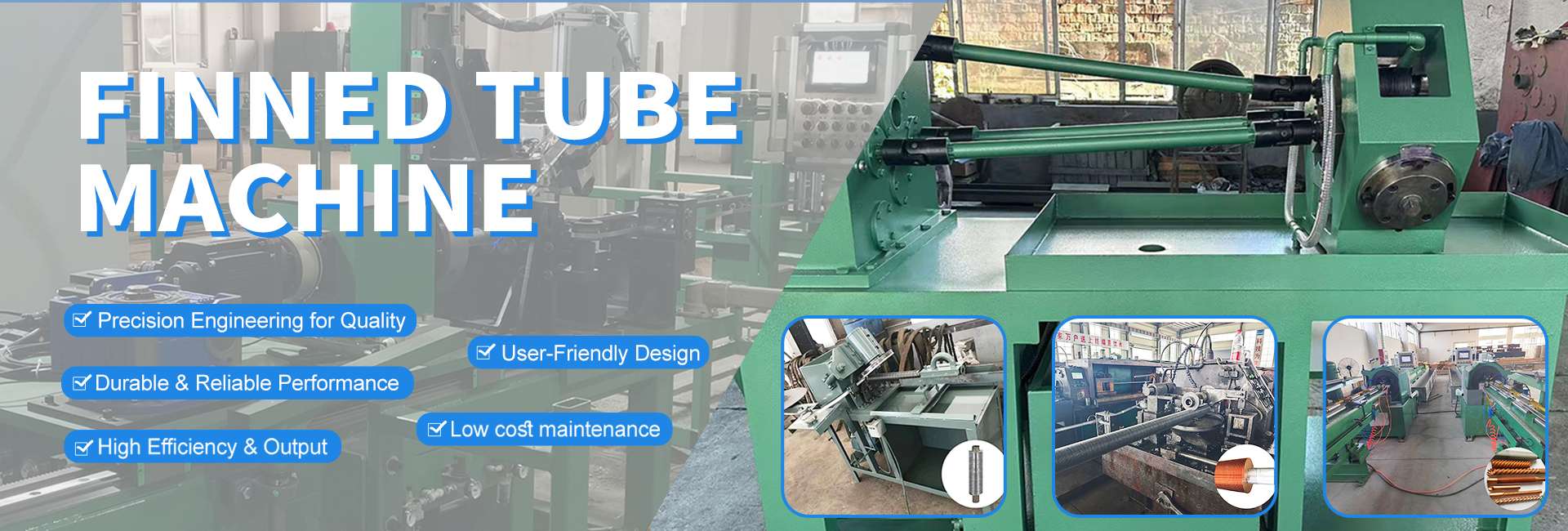

Les Machine à souder les ailettes au laser consists of a tube feeding line, automatic fin strip feeding unit, laser welding head, cooling system, and PLC/HMI control interface. The system is engineered for precision welding, and the machine can process carbon steel, stainless steel, and alloy material for production.

4. Caractéristiques principales

* High-precision laser welding technology

* Consistent and strong bonding of fins to the base tube

* Minimum distortion and heat-affected zone

* Processing of various materials and tube diameters

* Automated and PLC-controlled operation

5. Détails techniques

* Tube diameter: 25–80 mm

* Fin thickness: 0.5–1.5 mm

* Welding speed: 1–2 meters/minute

* Processing material: Carbon steel, stainless steel, and alloy steel

* Power: 2–6 kW laser source (customizable as needed)

6. Les avantages

* Fin tube has a stronger bonding compared to traditional welding

* The fin tube has a long service life

* High production efficiency and consistency

* The laser welding fin tube machine has low maintenance cost

* Energy-efficient and eco-friendly operation

7. Applications

* Petrochemical heat exchangers

* Power plant boilers

* Industrial air coolers

* Offshore and marine heat exchangers

* Waste heat recovery units

8. FAQ

Q1: How does laser welding compare to high-frequency welding?

Laser welding for fins creates a stronger, cleaner, and deeper weld with less thermal damage. This, in turn, creates a longer service life of fin tubes produced using the technology compared to traditional methods.

Q2: Can it handle stainless steel fins?

Yes, the laser welding fin tube machine can process stainless steel, carbon steel, and alloy fins.

Q3: Is operator training required?

Only basic training is needed as the machine is easy to use and automated with a PLC touchscreen interface.