Table des matières

- Introduction

- What is an Machine à fabriquer des tubes à ailettes extrudées?

- Description du produit

- Caractéristiques principales

- Détails techniques

- Avantages

- Applications

- FAQ

1. Introduction

Les machine pour tubes à ailettes extrudées is an efficient production system used to create extruded fin tubes with high-strength. Extruded fin tubes are a common heat exchanger type applied in the petrochemical, power generation and HVAC industry.

2. What is an Machine à fabriquer des tubes à ailettes extrudées?

An machine pour tubes à ailettes extrudées is a production equipment that produces fins that are mechanically bonded to a base tube by extrusion. It is one of three types of fin tubes, the others being welded and embedded. The extruded fin is mechanically solid and has high corrosion and thermal stress resistance.

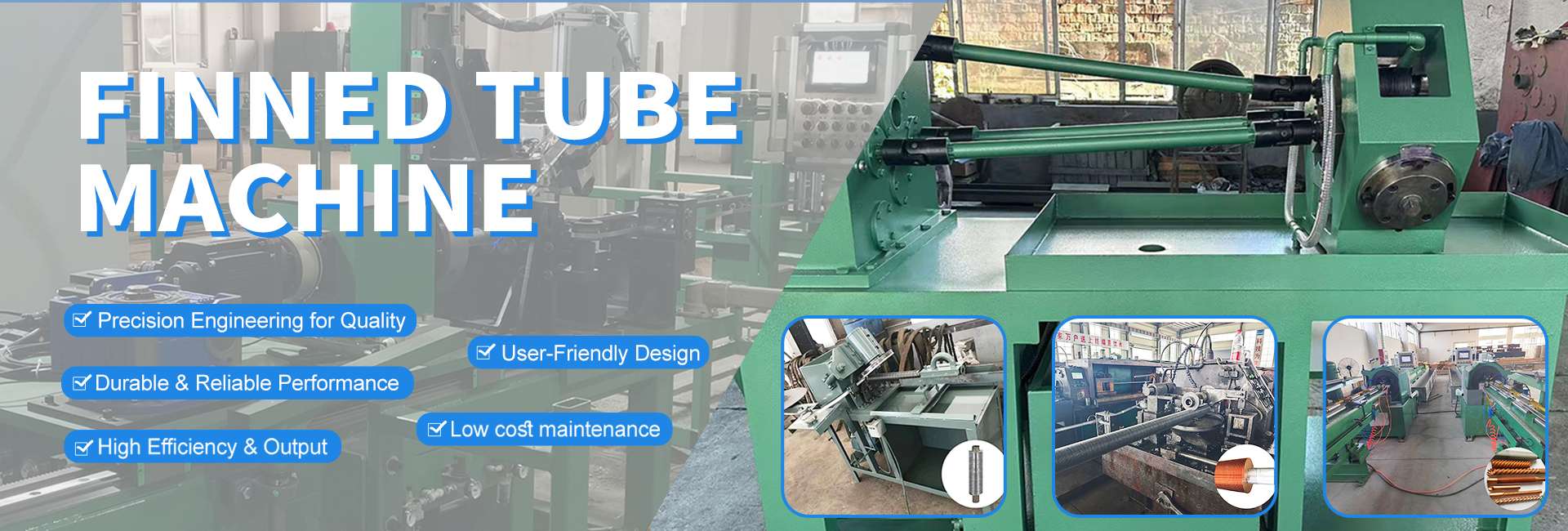

3. Description du produit

This production line includes a tube feeding mechanism, a fin rolling and extrusion unit, a cooling system, and a PLC control panel. The machine pour tubes à ailettes extrudées can accommodate a wide range of base tube materials, including copper, aluminum, and stainless steel, to meet various industrial needs.

4. Caractéristiques principales

* Produces high-strength extruded fins for fin tubes.

* Equipped with an automatic feeding and cutting system.

* Capable of processing a wide range of materials and fin thickness.

* Provides high precision and stable performance.

* Features PLC touchscreen operation.

5. Détails techniques

* Tube diameter: 12–63 mm

* Fin thickness: 0.3–1.2 mm

* Fin height: 5–16 mm

* Materials: Aluminum, copper, stainless steel, and other alloys

* Production speed: Up to 1000 meters per day

6. Les avantages

* Strong mechanical bond between the fin and the tube.

* Excellent corrosion resistance and wear resistance.

* Longer service life of finned tubes.

* High thermal efficiency, suitable for demanding applications.

* Suitable for large-scale production.

7. Applications

* Power plant heat exchangers

* Petrochemical industry coolers

* Air conditioning and refrigeration

* Gas and oil processing equipment

* Marine and offshore heat exchangers

8. FAQ

Q1: What’s the difference between extruded and welded fin tubes?

A: Extruded fins are mechanically bonded for superior strength and corrosion resistance, while welded fins are heat bonded.

Q2: Can this machine handle stainless steel tubes?

A: Yes, this machine is suitable for stainless steel, aluminum, copper and other alloys.

Q3: Is it complicated to maintain?

A: No, it only needs to be lubricated and inspected regularly. This machine can run for years without problems.