Tube Fin Machine for Efficient Heat Exchanger Manufacturing

Table des matières

Introduction

Qu'est-ce qu'un Machine à tubes à ailettes basses

Description du produit

Main Features

Technical Specifications

Avantages

Applications

Principe de fonctionnement

FAQ

Related Products

References

Introduction

A Machine à tubes à ailettes basses, also known as Tube Fin Machine, is a device used to produce low fin tubes for industrial heat exchangers.

These machines enhance heat transfer performance by forming spiral fins on the outer surface of tubes.

Tube Fin Machines are essential for efficient heat exchangers, boosting performance in condensers, evaporators, and air-cooled units.

Learn more about heat exchangers and fin technology for the science behind heat transfer efficiency.

Qu'est-ce qu'un Machine à tubes à ailettes basses

A Machine à tubes à ailettes basses, also known as Tube Fin Machine, is a machine used to create low fin tubes by forming helical fins on the outer surface of tubes through cold rolling or extrusion processes.

Tube fin machines provide an efficient way to increase the heat transfer efficiency of heat exchangers by increasing the external surface area of tubes, promoting better heat dissipation between fluids.

Les Tube Fin Machine features a precision fin forming mechanism that ensures uniform fin height and pitch, smooth surfaces, and strong mechanical bonding.

The resulting spiral fins are typically 0.5–1.3 mm high and are formed directly from the tube wall without additional material, making the process economical and efficient.

Description du produit

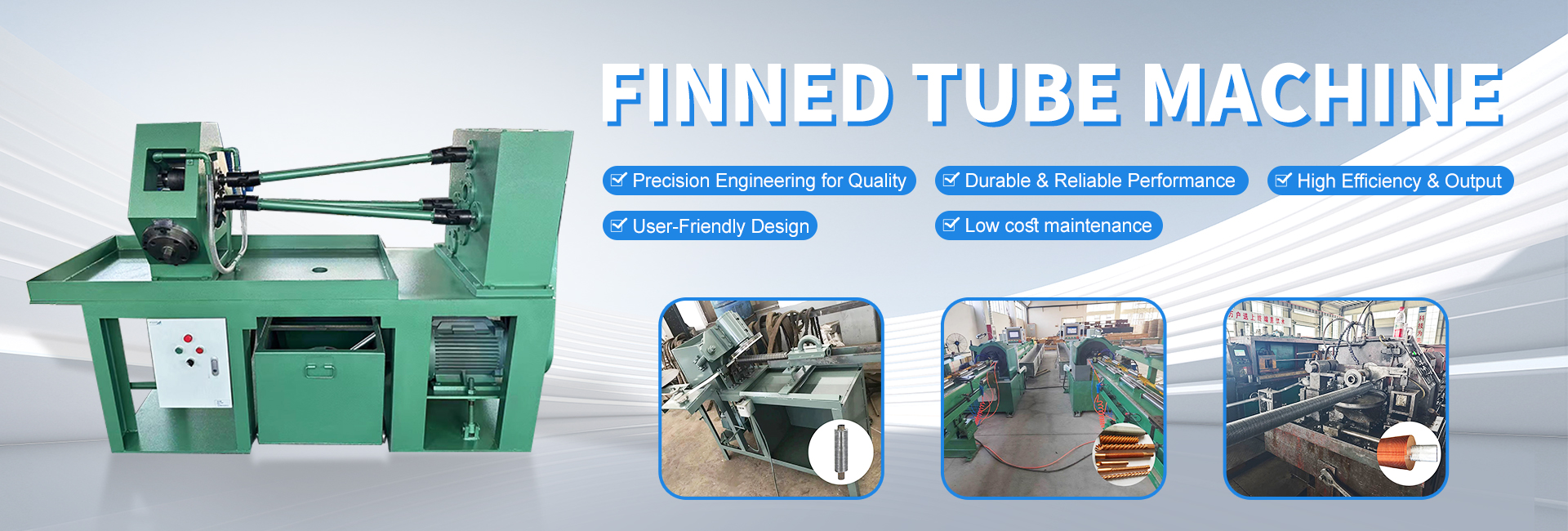

Our Machine à tubes à ailettes basses is a fully automatic continuous production device, featuring a high degree of accuracy and excellent stability.

Les Machine à tubes à ailettes basses rolls the fins on the outer surface of the tube by rotating rolling tools with a low fin height, ensuring the original strength of the tube material is not damaged, without any cracks or deformation.

Tube Fin Machine for tube finning, with excellent bending formability, is suitable for producing low fins on many kinds of tube materials, such as copper tube, aluminum tube, stainless steel tube, and brass tube.

Tube Fin Machines are widely used in the production of heat exchangers, condensers, boilers, chillers, etc., in various industries such as power plants, petrochemical, refrigeration, air conditioning, and so on.

All Tube Fin Machines are produced in accordance with ASME standards, and the main materials used are ASTM International certified.

Low Fin Tube Machine Main Features

- Precision fin rolling mechanism ensures high quality

- Adjustable fin height, pitch, and tube diameter

- Servo-driven system with PLC control

- Compatible with various tube materials

- Continuous production mode

- Low noise, low vibration, easy maintenance

- Optional automatic feeding and cutting device

Low Fin Tube Machine Technical Specifications

Parameter | Spécifications |

Tube Outer Diameter | 8–38 mm |

Hauteur des ailerons | 0.3–1.3 mm |

Pitch de l'aileron | 0.5–3 mm |

Tube Length | up to 12 meters |

Fin Forming Method | Cold Rolling / Extrusion |

Matériaux | Copper, Aluminum, Stainless Steel, Brass |

Alimentation électrique | 380V / 50Hz / 3 Phase |

Control System | PLC + Touch Screen Interface |

Advantages of Machine à tubes à ailettes basses

- Increased Heat Transfer Efficiency: The low fins increase the effective surface area, leading to better heat dissipation.

- Compact Design: Low noise and small footprint suitable for continuous factory production.

- Material Flexibility: Compatible with different tube materials.

- Long Service Life and Precision: Designed for long-term use with hardened steel rollers and precision bearings.

- Energy Saving and Low Waste: Optimized power consumption and minimal material waste.

- World-Class Standards: Manufactured under ISO and ASME standards.

Les Tube Fin Machine is a cost-effective and reliable finning equipment for heat exchanger manufacturers, providing a long-term finned tube solution.

Applications

Les Machine à tubes à ailettes basses and Tube Fin Machine are used to produce tubes for a variety of heat exchangers such as:

- Condenseurs de centrales électriques

- Air coolers / Air coolers and evaporators

- Refrigeration and HVAC systems

- Petrochemical and refinery heat exchangers

- Boiler economizers

- Marine heat transfer equipment

The tubes made by the Machine à tubes à ailettes basses and Tube Fin Machine are widely used in industrial heat exchangers as finned tubes for critical heat transfer applications.

Principe de fonctionnement

Les Machine à tubes à ailettes basses and Tube Fin Machine works by feeding a smooth tube into a rotating fin rolling head.

A roller set on the fin rolling head applies pressure on the outer surface of the tube and plastically deforms it into a spiral fin shape.

The cold forming process not only increases the heat transfer area but also hardens and strengthens the tube structure.

The entire Tube Fin Machine process is controlled by a PLC system, which makes the equipment more stable, accurate and repeatable.

The fin height, pitch, and feeding speed can be adjusted by digital setting, allowing the user to fine-tune the operation parameters for different materials and applications.

FAQ

Q1: What’s the difference between Low Fin Tube and High Fin Tube?

A: Low fin tubes have short and closely spaced fins, ideal for compact exchangers. High fin tubes have taller and more widely spaced fins for larger surface area.

Q2: What materials can be processed by Tube Fin Machine?

A: The Tube Fin Machine can process Aluminum, copper, brass, stainless steel, and titanium tubes.

Q3: Can the Machine à tubes à ailettes basses be customized?

A: Yes, the fin pitch, fin height, and tube diameter of the Machine à tubes à ailettes basses can be customized according to your heat exchanger design.

Q4: What industries use finned tubes made by the Machine à tubes à ailettes basses?

A: HVAC, petrochemical, refrigeration, power generation and other industries use finned tubes made by the Machine à tubes à ailettes basses.

Call to Action

Contact us today to get a customized Extruded Fin Tube Machine solution.

WhatsApp | 📧 Email | 📄 Get a Quote