Table des matières

Introduction

Description du produit

Caractéristiques principales

Détails techniques

Avantages

Applications

FAQ

Related Products

References

Description

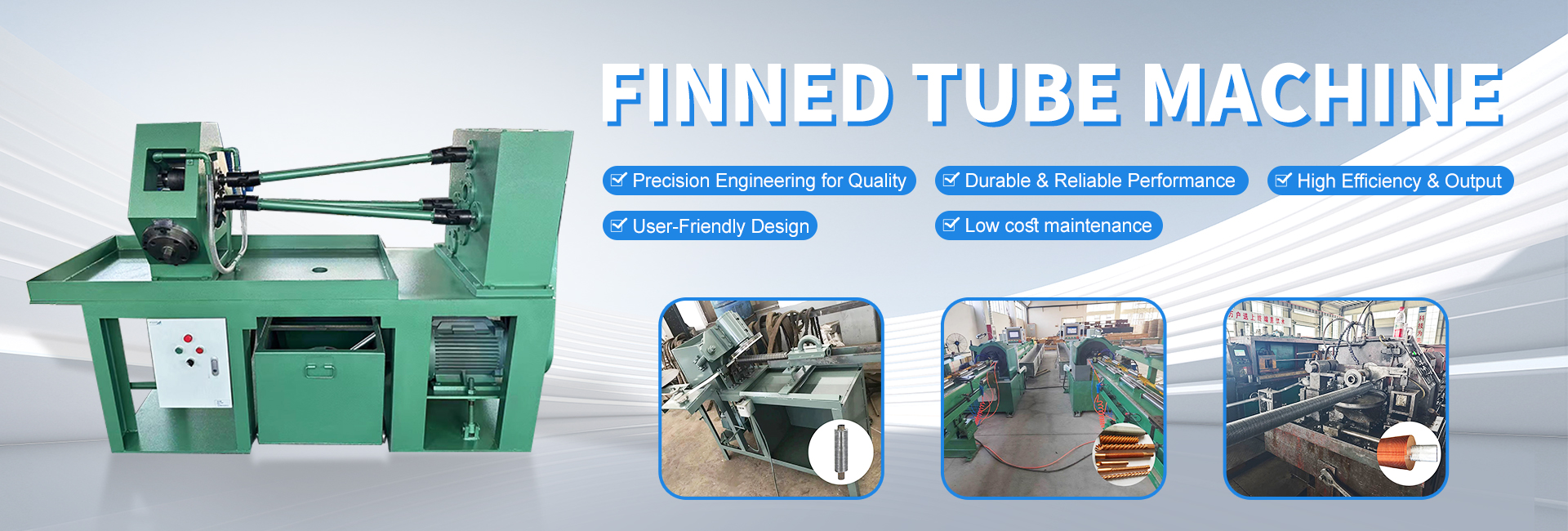

Les Spiral Fin Tube Welding Machine is used for continuous welding of spiral fin tubes for industrial heat exchangers.This equipment can produce uniform fin-to-tube welding with good heat transfer effect and service life.

Product Features

Les Spiral Fin Tube Welding Machine uses high frequency welding or solid state welding to metallurgically bond the tube to the fin .Suitable for carbon steel, stainless steel and alloy steel plates.

Servo feeding, fin tension adjustment, PLC control system, etc., all movements are automated and accurate.The entire production process is ASME certified and all materials comply with ASTM standards

Détails techniques

Parameter | Spécifications |

Diamètre du tube | 19–114 mm |

Hauteur des ailerons | 5–16 mm |

Pitch de l'aileron | 2.5–10 mm |

Matériau de l'aileron | Carbon Steel / Stainless Steel |

Matériau du tube | CS, SS, Alloy Steel |

Welding Method | High-Frequency / Solid-State |

Alimentation électrique | 200–300 kW |

Control System | PLC + HMI Touchscreen |

Features

Adopt high frequency welding or solid state welding method, good fin bonding

- Fin pitch, fin height and tube diameter can be adjusted

- PLC + HMI Touchscreen control system, convenient parameter setting and on-line monitoring

- Automatic loading and cutting of the tube

- Power saving equipment, low power loss

- Low maintenance and stable production

Benefits

- Strong welding bond: Metallurgical bond between the fin and the tube, ensuring the best heat transfer effect.

- Long service life: Resistant to corrosion and thermal fatigue.

- High efficiency: Stable continuous automatic production, short downtime.

- Energy saving and environmental protection: Low power loss and material loss.

- In line with international quality standards: Strictly in accordance with ISO and ASME standards.

Applications

- This Spiral Fin Tube Welding Machine is mostly used in

- Power plant and heat recovery plant

- Petrochemical and refinery heat exchangers

- Air coolers and condensers

- Gas heater and economizers

- Marine and offshore heat transfer units

FAQ

Q1. What is the difference between spiral fin and extruded fin tubes?

- Spiral fin tube is welded tube and extruded fins are attached by mechanical bond on tube. Welded fins have flexible option for high temperature service.

Q2. Can the machine weld stainless steel tube?

- Yes, this machine is available for all types of material such as stainless steel, carbon steel, alloy steel.

Q3. Can we change the fin pitch and height?

- Yes, the PLC based system can adjust the fin pitch and height easily.

Call to Action

Contact us today to get a customized Extruded Fin Tube Machine solution.

WhatsApp | 📧 Email | 📄 Get a Quote