1. Introducción

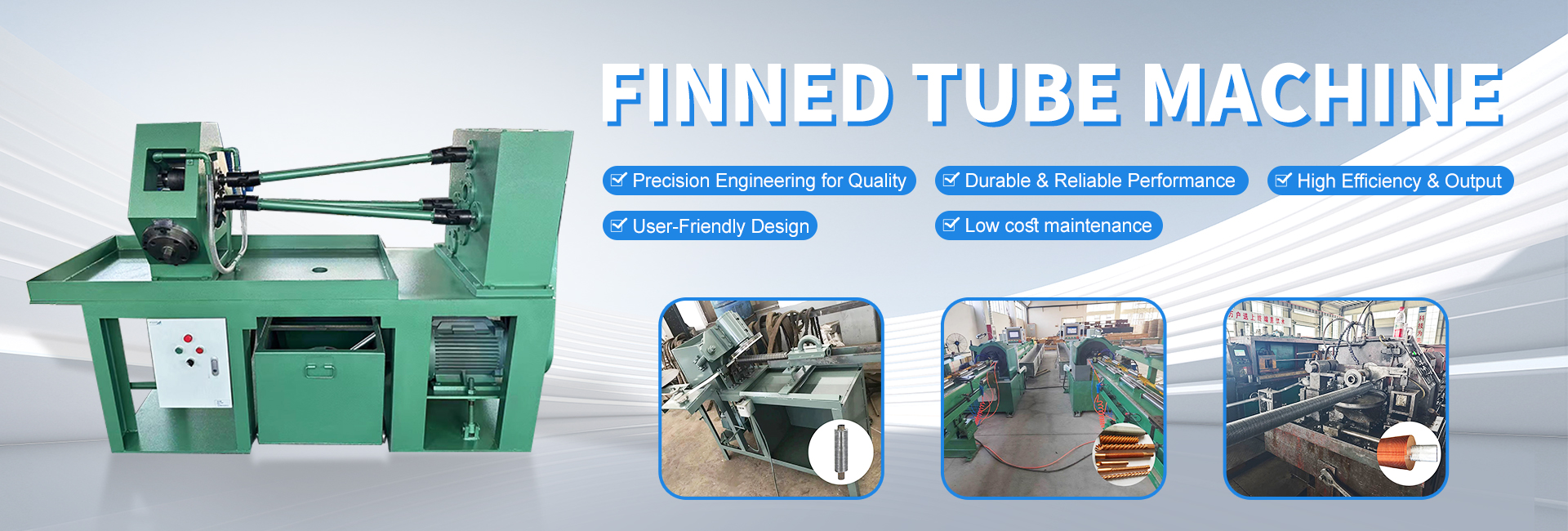

Industries need efficient heat transfer equipment to ensure a smooth operation. For that reason, many factories opt to use spiral finned tubes for stable and long-term thermal performance. A spiral finned tube machine allows manufacturers to boost their production speed and the quality of fins. Bangwin Thermal can provide you with the most advanced finning solutions via customindustrialheatexchanger.com.

2. What Is a Spiral Finned Tube

A spiral finned tube features steel fins tightly wrapped around a base tube. The spiral shape increases the total surface area, which further enhances the heat transfer efficiency. Therefore, many heat exchangers employ spiral fins for long-term heat transfer.

ASME Heat Exchanger Standards – https://www.asme.org/

3. How a Spiral Finned Tube Machine Works

A modern spiral finned tube machine winds metal strips tightly around tubes by applying great mechanical forces. This mechanism can greatly improve heat transfer efficiency and mechanical stability.

Here is a simplified general working flow:

- Load the base tube

- Feed the steel fin strip

- Turn on the high-torque winding system

- Control the fin pitch and fin height

- Create uniform spiral fins

- Cut the tube to required length

The machine also maintains a stable tension and crisp edges of the fins.

4. Main Parts of Spiral Finned Tube Machine

Main parts of your machine are:

- Tube Loading System

- Ensure stable support for long tubes.

- Fin Strip Feeder

- Provide stable feeding of steel strip.

- High-Torque Winding Head

- Achieve accurate winding of spiral fins.

- Servo Motor Drive

- Precisely control tube rotation.

- Fin Pitch Controller

- Adjust fin pitch with precision.

- Hydraulic Cutting System

- Generate clean-cut tube ends.

Bangwin Thermal designs every part with robust rigidity and high robustness.

5. Features and Technical Advantages

A spiral finned tube machine has many functional features. More so, each feature can enhance production capacity.

- High-speed winding

- Clean edges of the fins

- Uniform pitch of the fins

- Adjustable pitch and height

- Mechanical bonding with good strength

- Tube with smooth rolling

- Larga vida útil

- Low energy consumption

The above advantages make the machine a preferred machine among manufacturers of spiral fins.

6. Benefits of Spiral Fins in Heat Exchanger Production

Factories using spiral finned tube machines enjoy great benefits.

- Transferencia de calor mejorada

Improved surface area leads to more thermal efficiency.

- Improved Tube Strength

Closer winding leads to good bonding between tube and fin.

- Dust Resistant Fin Design

Curved fins can reduce dust deposits.

- Mayor durabilidad

Fins are vibration and temperature shock resistant.

- Flexible Parameters

Height, pitch, and material of the fins can be adjusted.

The above benefits can meet the requirements of various industries that have very high expectations for product performance.

7. Where are spiral finned tubes used?

Spiral fins are widely used in the following heat transfer equipment:

- Economizadores de caldera

- Enfriadores de gas

- Oil coolers

- Air preheaters

- Heat recovery devices

- Petrochemical heaters

- Power plant heat exchangers

- Industrial drying equipment

The spiral fin is suitable for high temperature and large flow applications.

8. Why Choose Bangwin Thermal?

Bangwin Thermal supplies complete finning technology to factories all over the world. We can also design the finning machines in accordance with your project requirements. Technical solutions are also available on our official website customindustrialheatexchanger.com.

You can enjoy:

- Durable machine bodies

- Precision in finning

- Thorough technical guidance

- Tailored equipment choices

- Timely delivery

- Dependable global service

All these advantages will lead to a stable production line of fin tubes.

9. PREGUNTAS FRECUENTES

- What is a spiral finned tube machine?

It is a device that uses constant mechanical power to wind steel fins around tubes.

- What fin materials does it support?

It supports carbon steel, stainless steel, and alloy fins.

- Can the machine adjust the fin pitch?

Yes. The pitch, height and thickness are easily adjusted.

- Does it support long tubes?

Yes. Bangwin Thermal machines support long and heavy tubes.

- Where can I get technical help?

You can contact Bangwin Thermal through customindustrialheatexchanger.com.

10. Conclusión

A spiral finned tube machine can greatly enhance the production of fins, as well as the performance of heat exchangers. This technology has gained a good reputation in various industries because of its strong mechanical bonding, as well as the ability to customize fin designs. Bangwin Thermal continues to provide quality equipment, st rong engineering support and long-term service to its customers through customindustrialheatexchanger.com.