Introducción

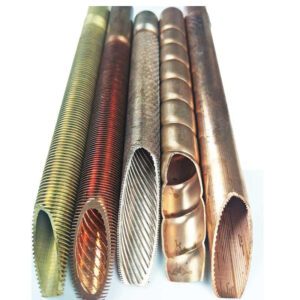

En Tubo de aleta baja is a type of heat transfer tube with a low fin on the outer surface, used to increase the surface area and improve heat transfer performance. With its unique low fin design, the Low Fin Tube is widely used in industries such as oil refining, HVAC, refrigeration and power generation.

It is known for its high heat transfer efficiency, compact structure, and long service life, making it a cost-effective solution for modern intercambiador de calor systems.

Product Details

- Product Name: Tubo de aleta baja

- Material: Copper, Aluminum, Carbon Steel, Stainless Steel

- Fin Type: Integrated Low Fin

- Fin Height: Generally 1.0–5 mm

- Application: Heat exchangers, condensers, evaporators

- Customization: Length, diameter, and fin parameters can be customized as per customer’s requirements.

Features

✅High heat transfer efficiency

✅Compact size with larger external surface area

✅Corrosion-resistant and mechanical stress resistant

✅Uniform fin structure for consistent performance

✅Compatible with various tube materials and diameters

✅Easy installation and integration into existing systems

Detalles técnicos

Parámetro | Especificación | Unit |

Outer Diameter (OD) | 12.7–38.1 | mm |

Altura de la aleta | 1.0–2.5 | mm |

Paso de aletas | 19–26 | FPI (Fins Per Inch) |

Material del tubo | Copper / Aluminum / Steel | — |

Tube Length | Up to 12 | m |

Fin Type | Integral Low Fin | — |

Working Temperature | Up to 350 | °C |

Specifications

- Parameter Specification Unit

- Outer Diameter (OD) 12.7–1 mm

- Fin Height 1.0–5 mm

- Fin Pitch 19–26 FPI (Fins Per Inch)

- Tube Material Copper / Aluminum / Steel

- Tube Length Up to 12 m

- Fin Type Integral Low Fin —

- Working Temperature Up to 350 °C

Ventajas

- High heat transfer efficiency due to increased surface area

- Energy-efficient operation, leading to cost savings

- Durable and reliable, with corrosion-resistant materials

- Flexible design for different diameters and fin configurations

- Easy to clean and low fouling tendency, reducing maintenance requirements

Aplicaciones

- Petrochemical industry: used in heat recovery systems and condensers

- Refrigeration & HVAC: commonly found in air conditioners, chillers, and evaporators

- Power generation: used in steam condensers and cooling systems

- Chemical processing: utilized in reactors and cooling jackets

Principio de funcionamiento

En Tubo de aleta baja works by increasing the outside surface area of the tube without increasing the inside diameter. This allows for more efficient heat transfer between fluids, resulting in improved performance of the intercambiador de calor.

Compared to high fin tubes, the Tubo de aleta baja has a lower fin height, which provides a balance between efficiency and compact size, making it suitable for a wide range of industrial applications.

Certifications & Quality

- ISO 9001 Certified Factory

- 100% Dimensional & Surface Inspection

- Customized Packaging for Export

PREGUNTAS FRECUENTES

Q1: What materials can be used for Low Fin Tubes?

A1: We offer copper, aluminum, carbon steel, and stainless steel options to meet the requirements of different projects.

Q2: Are the tube length and fin size customizable?

A2: Yes, all parameters including tube length and fin size can be customized according to your technical drawings or specifications.

Q3: What is the lead time for delivery?

A3: Standard products can be delivered within 7–15 days. Customized products may take 20–30 days to ship.

Llamamiento a la acción

👉 Contact us today for a customized Low Fin Tube solution.

📞 WhatsApp | 📧 Email | 📄 Solicitar presupuesto