Soldadura de alta frecuencia Tubo de aleta – High Thermal Efficiency Heat Transfer Fin Tube

Introducción

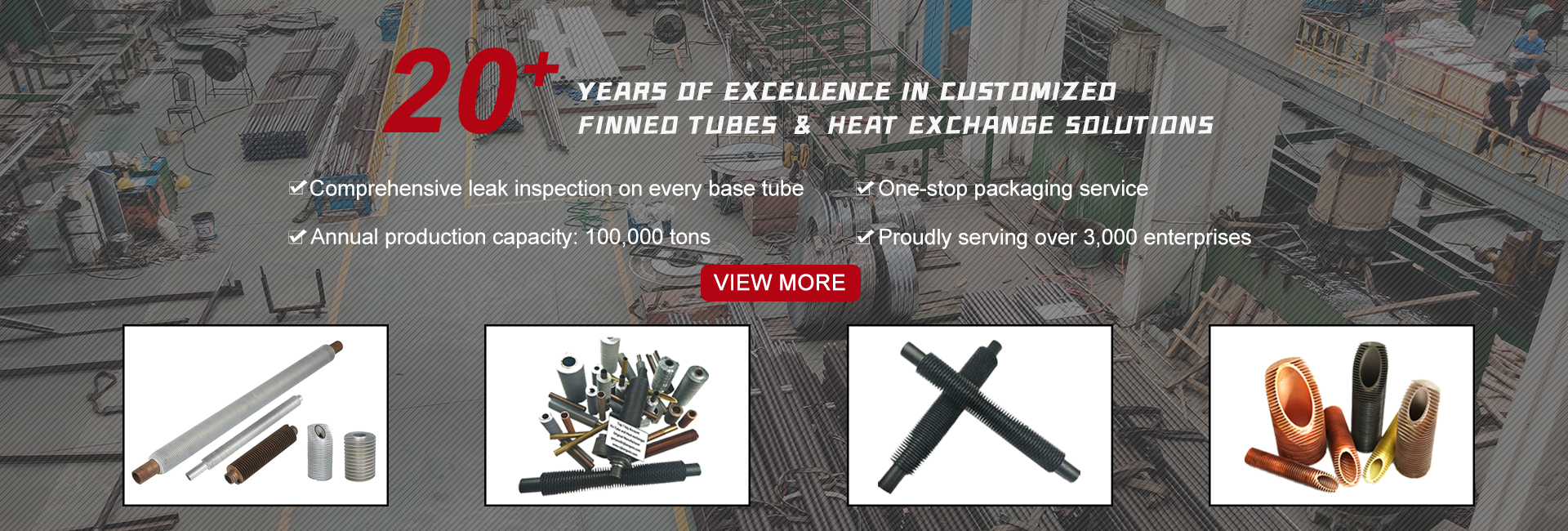

En Soldadura de alta frecuencia Tubo de aleta is an advanced high-performance heat transfer component that uses high frequency resistance welding technology to permanently weld the fins to the tube surface, resulting in excellent adhesion strength, thermal conductivity, and durability in harsh environments.

This fin tube is commonly used in power generation, petrochemical, HVAC, and boiler industries.

Descripción del producto

- Product Name: Soldadura de alta frecuencia Tubo de aleta

- Material: Carbon Steel, Stainless Steel, Alloy Steel

- Fin Type: Solid or Serrated Spiral Fin

- Fin Bonding: High-frequency resistance welding

- Application: Heat exchangers, boilers, air coolers, condensers, heaters

- Certification: ISO, CE, SGS

- Delivery: Standard & custom

Características principales

- Permanent and strong fin-to-tube bonding

- Rendimiento superior en transferencia de calor

- Corrosion and oxidation resistant

- Suitable for high-temperature and high-pressure applications

- Customizable fin height, thickness, and pitch

- Larga vida útil y bajo mantenimiento

Detalles técnicos

- Parameter Specification Unit

- Tube Outer Diameter (OD) 25–219 mm

- Fin Height 10–30 mm

- Fin Thickness 1.0–0 mm

- Fin Pitch 2.5–20 mm

- Tube Material Carbon Steel / Stainless Steel / Alloy —

- Fin Material Carbon Steel / Stainless Steel —

- Fin Bonding High Frequency Resistance Welding —

- Max Working Temperature up to 400 °C

Ventajas

- High Mechanical Strength: Welded fins provide stable performance even at high temperatures and pressures.

- Better Heat Transfer: Continuous metal bonding ensures excellent thermal conductivity.

- High Durability: Excellent resistance to vibration, corrosion, and thermal fatigue.

- Flexible Design: Available in a wide range of tube and fin sizes to suit different applications.

- Low Maintenance: Long service life reduces replacement costs and downtime.

Aplicaciones

- Power Plants – heat recovery, boilers, air coolers

- Petrochemical Industry – process heaters, condensers

- HVAC Systems – air heating and cooling coils

- Refineries & Fertilizer Plants – gas cooling and heating

- Industrial Furnaces – heat exchangers, economizers

- Image Alt tag: “Welded fin tube used in industrial boiler heat exchanger”

Principio de funcionamiento

En Soldadura de alta frecuencia Tubo de aleta is manufactured by feeding the fin strip into a high-frequency welder and continuously winding it onto the base tube. The welding machine uses electromagnetic induction to generate heat, which results in strong metallurgical bonding between the fin and the tube without any filler material.

This process ensures high heat transfer performance and structural strength.

Certifications & Quality

- ISO 9001 Certified Manufacturing

- SGS / CE Quality Inspection

- 100% Weld Strength Testing

- Envases para la exportación

PREGUNTAS FRECUENTES

Q1: What is the difference between welded fin tube and tubo de aleta extruida?

A1: Welded fin tubes have high frequency welding for stronger bonding and are more suitable for high-temperature applications.

Q2: Can the fin dimensions be customized?

A2: Yes, fin height, thickness, pitch, and tube material can be customized.

Q3: How long does it take for delivery?

A3: For standard sizes, we can ship within 15–20 days; custom orders usually take 25–35 days.

Llamamiento a la acción

Póngase en contacto con nosotros Soldadura de alta frecuencia Tubo de aleta solución.

WhatsApp | 📧 Correo electrónico | 📄 Solicitar presupuesto