Inhaltsübersicht

- Einführung

- Was ist ein H Type Fin Tube Machine?

- Beschreibung des Produkts

- Wesentliche Merkmale

- Technische Details

- Vorteile

- Anwendungen

- FAQs

1. Einleitung

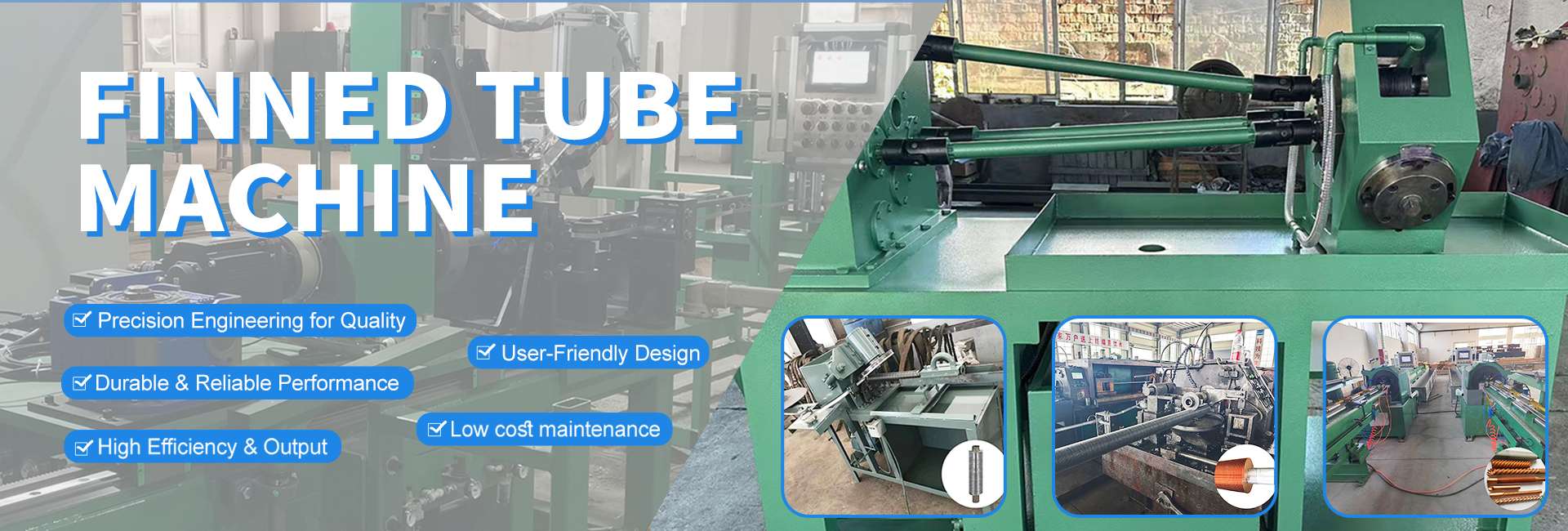

Die H type fin tube machine is an industrial device used for manufacturing H-shaped finned tubes. These tubes have a larger surface area, higher heat transfer efficiency, and durability, which make them an ideal choice for heat exchanger applications.

2. Was ist ein H Type Fin Tube Machine?

Eine H type fin tube machine is an advanced welding and forming system used to attach H-shaped fins to the base tubes. The resulting structure enhances turbulence and airflow, resulting in improved heat exchanger performance in demanding industrial applications.

3. Produkt Beschreibung

Die H type fin tube machine consists of a fin forming unit, automatic feeding system, welding station, cooling system, and a PLC-based control interface. The machine is designed to offer high precision and efficiency, ensuring uniform and consistent fin bonding and long-lasting tube performance.

4. Hauptmerkmale

* High level of automation with PLC control

* Strong fin to tube welding bond

* Capable of processing various base tube materials

* Adjustable fin height and spacing

* Continuous production for large-scale manufacturing

5. Technische Einzelheiten

* Tube diameter: 25–80 mm

* Lamellenstärke: 0,3-1,2 mm

* Fin material: Carbon steel, stainless steel

* Welding method: High-frequency resistance welding

* Production speed: Up to 1500 fins/hour

6. Vorteile

* Can be used to produce high-efficiency H type finned tubes

* Enhances durability and corrosion resistance

* Energy-saving and stable production

* Easy to maintain and operate

* Suitable for long production runs

7. Anwendungen

* Power plant boilers

* Petrochemical heat exchangers

* Industrial air coolers

* Waste heat recovery systems

* Large-scale HVAC systems

8. FAQs

Q1: What makes H type fins better than other fin types?

A: The H shape creates more turbulence and surface area, which improves the heat transfer efficiency and reduces fouling.

Q2: Can the machine handle different fin materials?

A: Yes, the machine supports carbon steel, stainless steel, and alloy fins.