Inhaltsübersicht

* Product Description

* Key Features

* Technical Details

* Advantages

* Applications

* FAQ

* Related Products

* References

Einführung

Die Maschine für extrudierte Rippenrohre is a vital industrial machine for manufacturing high-performance heat exchangers.

The machine extrudes fins to the base tubes, enhancing thermal conductivity and system durability.

Fins are bonded to tubes under heat and pressure, forming a monolithic structure with superior thermal contact.

Check out our articles about Wärmetauscher and extended fins that offer higher heat transfer performance.

Beschreibung des Produkts

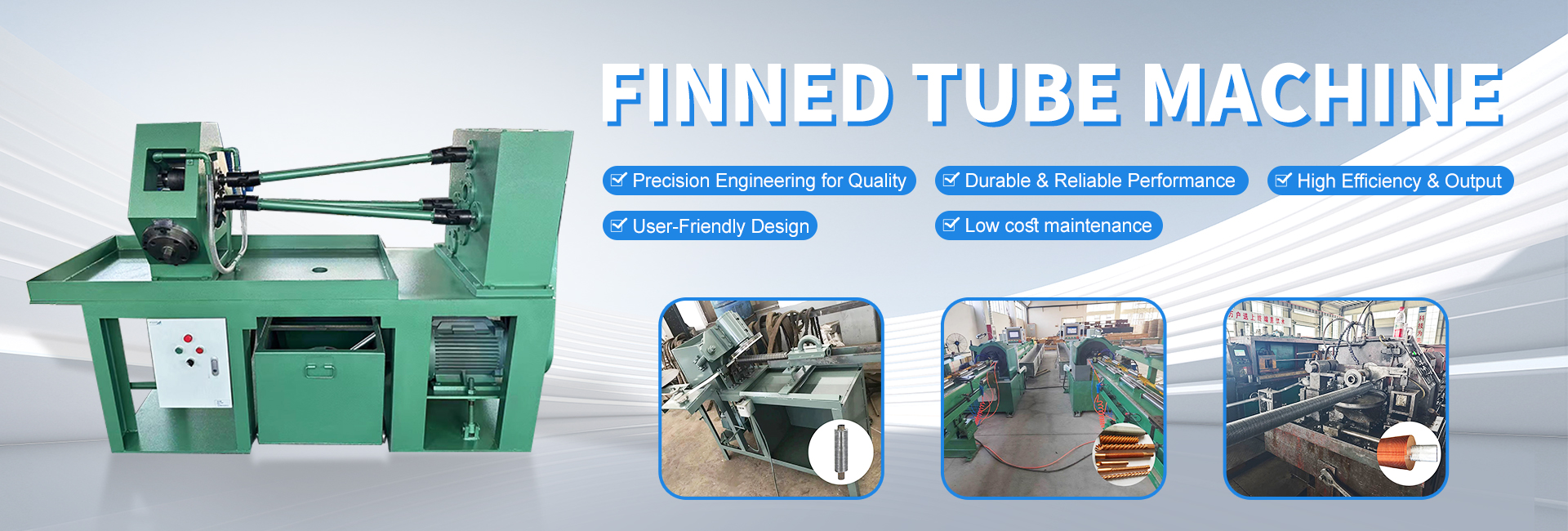

Our Maschine für extrudierte Rippenrohre is specially designed for the continuous and automatic production of finned tubes.

Made of high-grade aluminum, copper, or carbon steel, the fin tubes are created through an extrusion process.

The extrusion force creates a mechanical bond between the fin and tube surfaces, ensuring high thermal conductivity and extended service life.

All manufacturing procedures are in compliance with ASME, while raw materials meet the ASTM International standards.

Wesentliche Merkmale

- High extrusion force for stable and continuous fin forming

- Adjustable fin pitch and height for various product specifications

- Automatic tube feeding and cutting system for smooth operation

- Touch-screen PLC control for precise operations

- Suitable for aluminum, copper, and stainless steel tubes

- Low maintenance, energy-efficient design

Technische Details

Parameter | Spezifikation |

Tube Outer Diameter | 16–63 mm |

Flossenhöhe | 5–16 mm |

Flossenteilung | 2.5–10 mm |

Material | Aluminum, Copper, Steel |

Motor Power | 15–45 kW |

Fin Bonding Type | Mechanical Extrusion |

Control System | PLC + Touchscreen Interface |

Vorteile

- High Heat Transfer Efficiency – Fins and tubes are integrally bonded, forming a monolithic structure with superior thermal contact.

- Corrosion Resistance – The excellent bonding eliminates any moisture or air gaps.

- Energy-Saving Production – The continuous extrusion process saves raw materials with little to no waste.

- Strong Mechanical Strength – Fins are resilient under high temperature.

- Meet ISO and ASME standards for global and reliable application.

Learn more about ISO standards for manufacturing heat exchangers at ISO.org

Anwendungen

The Extruded Fin Tube Machine is widely used in

- Power plant condensers and boilers

- Petrochemical heat recovery systems

- Air coolers and gas coolers

- HVAC- und Kühlsysteme

- Marine and offshore Wärmetauscher

FAQ

Q1: What materials can be processed by this machine?

A: Aluminum, copper, carbon steel, and stainless steel tubes can be processed for extruded fin tubes.

Q2: What is the main advantage of extruded fin tubes over welded fin tubes?

A: Welded fins have solder joints which deteriorate under heat over time.

Extruded fins are mechanically bonded to the tube with no solder joints, providing higher thermal conductivity and corrosion resistance.

Q3: Can this machine be customized?

A: Yes, we offer fully customizable extrusion sizes, fin profiles, and levels of automation.

Call to Action

Contact us today to get a customized Extruded Fin Tube Machine Lösung.

WhatsApp | 📧 E-Mail | 📄 Angebot einholen