Table of Contents

Introduction

What Is an Extruded Fin Tube?

Product Description

Key Features

Detailed Structure

Advantages

Applications

FAQ

Introduction

In the world of industrial heat exchangers, the extruded fin tube is one of the most effective and widely used heat transfer components. The process of extrusion used in its fabrication offers many advantages such as better mechanical bond between tube and fins for higher heat transfer efficiency, excellent corrosion resistance, and longer service life than other fin tubes.

Extruded fin tube is ideally suited for severe duty applications in oil refineries, power plants, petrochemical plants, and even some marine applications.

What Is an Extruded Fin Tube?

In an extruded fin tube, a thick aluminum or copper sleeve is mechanically extruded on the outside surface of a base tube (carbon steel, stainless steel, copper-nickel, etc.). During extrusion, fins are formed as integral part of outer sleeve and bond seamlessly with tube surface without any gap or thermal resistance.

So, the extruded fin tube is a thick sleeve of aluminum or copper material extruded on a base tube with fins integrally formed from the sleeve material.

Product Description

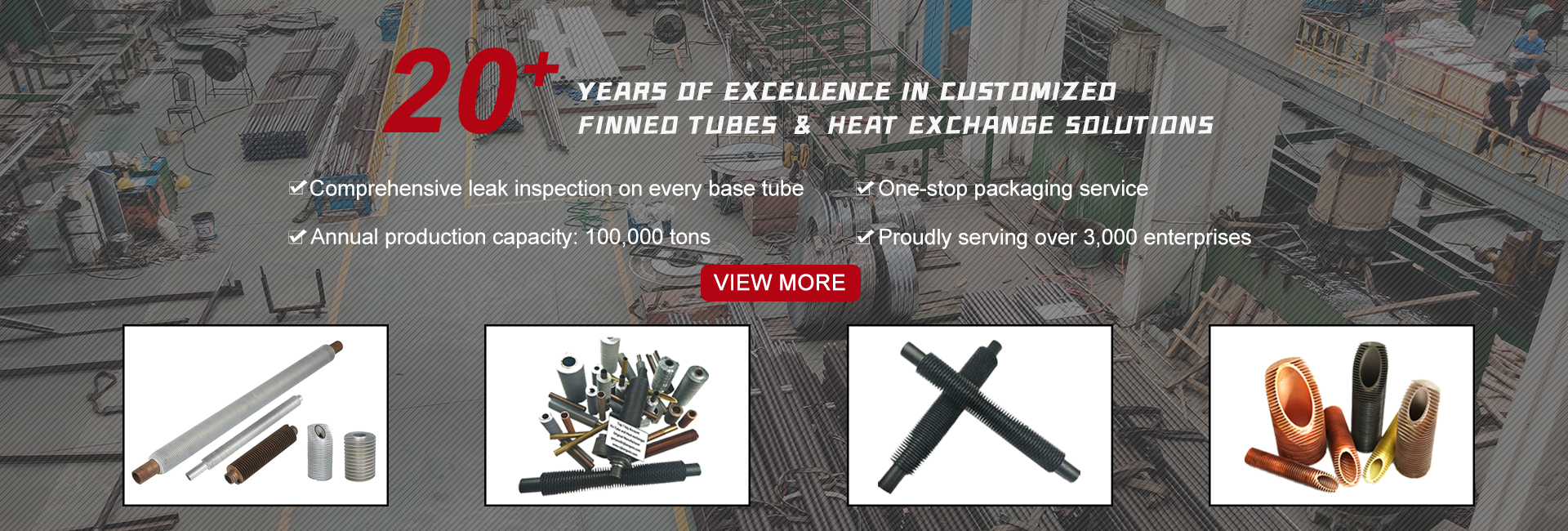

Bangwin’s Extruded Fin Tubes are used in air cooled heat exchangers, condensers, and gas coolers.

Each tube is manufactured using high precision extrusion technology, ensuring tight fin adhesion and uniform fin height. We can offer many types of base tube and fin materials, which can be customized for your specific project needs.

Specifications:

- Base tube: Carbon steel tube, stainless steel tube, copper-nickel tube, titanium tube

- Fin material: Aluminum fin, copper fin

- Fin height: 8–16 mm

- Fin thickness: 0.3–2 mm

- Tube OD: 19–50 mm

- Fin pitch: 10–11 FPI

Key Features

- Excellent fin-tube mechanical bonding

- Corrosion and oxidation resistant

- High thermal transfer efficiency

- Smooth internal tube surface for easy cleaning

- Wide temperature range (up to 320 °C for aluminum fins)

- Customizable materials and dimensions

Detailed Structure

- The typical extruded fin tube comprises the following:

- Base Tube: The inner tube that carries process fluid (steam, oil, or gas).

- Fin Sleeve: Thick aluminum or copper tube sleeve which is extruded over base tube.

- Fins: Continuous fins of metal, which are formed from sleeve during extrusion process and create metallurgical bond between fin and tube.

- This results in a very strong extruded fin tube with no air gaps between fin and tube (which is a big advantage over other fin types such as L-type fin tube and G-type fin tube).

Advantages

- High durability and resistance to vibration, thanks to strong metallurgical bond between fins and tube that does not loosen over time.

- Resistant to corrosion and pitting, making them suitable for marine/offshore or humid environments.

- Easy to clean and has long service life.

- Provides very high heat transfer efficiency due to high thermal conductivity of aluminum or copper, and complete metal contact between fin and tube.

- Can be customized as per your application and type of heat exchanger.

Applications

- Air Cooled Heat Exchangers (ACHE)

- Condensers and Evaporators

- Oil Refineries & Gas Processing Plants

- Power Generation Systems

- Petrochemical & Chemical Industries

- Marine and Offshore Cooling Systems

FAQ

Q1: What’s the difference between extruded fin tubes and L-type fin tubes?

A1: Extruded fins are integral and much stronger, with better corrosion resistance and longer service life.

Q2: Can I use extruded fin tubes in corrosive environments?

A2: Yes, especially with aluminum or copper fins, as they provide excellent corrosion protection.

Q3: What’s the typical fin height and thickness?

A3: Fin height is typically 8 mm to 16 mm; thickness is 0.3 mm to 1.2 mm.

Q4: Do you provide customized dimensions?

A4: Yes, we can manufacture tubes as per customer drawings and performance requirements.