Table of Contents

- Introduction

- What is a Low Fin Tube Machine

- Product Description

- Key Features

- Technical Details

- Advantages

- Market Trends & Sustainability

- Applications

- FAQs

1. Introduction

Low fin tube machine is an apparatus that produces tubes with external fins of low height, which significantly enhances the heat-transfer efficiency of [heat exchanger] units.

2. What is a Low Fin Tube Machine

The low fin tube machine forms external low fins of a uniform height on the surface of copper, aluminum, or stainless-steel tubes to increase the area available for heat transfer without increasing the overall tube diameter. It can roll the external fin profile of the tube in one pass of a fin-rolling head and is a popular choice for low-profile [shell and tube heat exchanger] design.

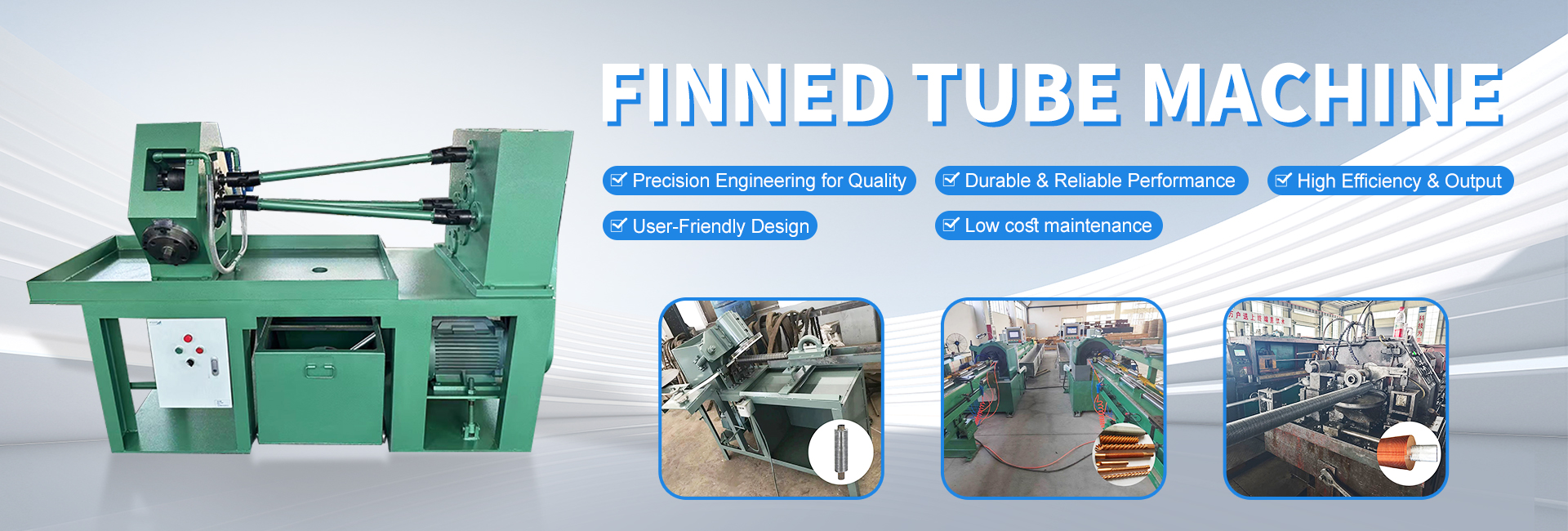

3. Product Description

The low fin tube machine has fin-rolling heads with precise height control, automatic tube feeding mechanism, and intelligent controls to ensure consistent finning with minimal deviation.

4. Key Features

- Adjustable fin pitch and depth

- High-speed finishing at up to 10 m/min

- Touchscreen PLC control with IoT capability

- Low energy requirements and quiet operation

5. Technical Details

- Tube diameter: 10–50 mm

- Fin height: 0.3–2 mm

- Tube materials: Copper, Aluminum, Stainless steel

- Tube power requirement: 5–12 kW

6. Advantages

- Significantly improved heat transfer without increase in tube diameter

- Suitable for high-pressure, high-temperature [heat exchanger] applications

- Compact and easy to fit into plant areas with low available space

- Easy to maintain with modular design

7. Market Trends & Sustainability

Energy-efficient [fin tube heat exchanger] design is becoming a popular choice with HVAC, petrochemical, and power industries, due to the advantages of the low fin tube. As the demand for low carbon emission production increases, it will also help to curb carbon footprint.

8. Applications

- [Shell and tube heat exchanger] fabrication

- Air-conditioning and refrigeration equipment

- Petrochemical plant

- Power plant condensers

9. FAQs

Q1: What tube materials can the machine work with?

A1: Copper, aluminum, and stainless steel.

Q2: Can it work continuously for a long time?

A2: Yes, the machine can run for long hours with minimum downtime for maintenance.