Table of Contents

- Introduction

- What is a High Frequency Welding Fin Tube?

- Product Description

- Key Features

- Technical Details

- Advantages

- Applications

- FAQs

1. Introduction

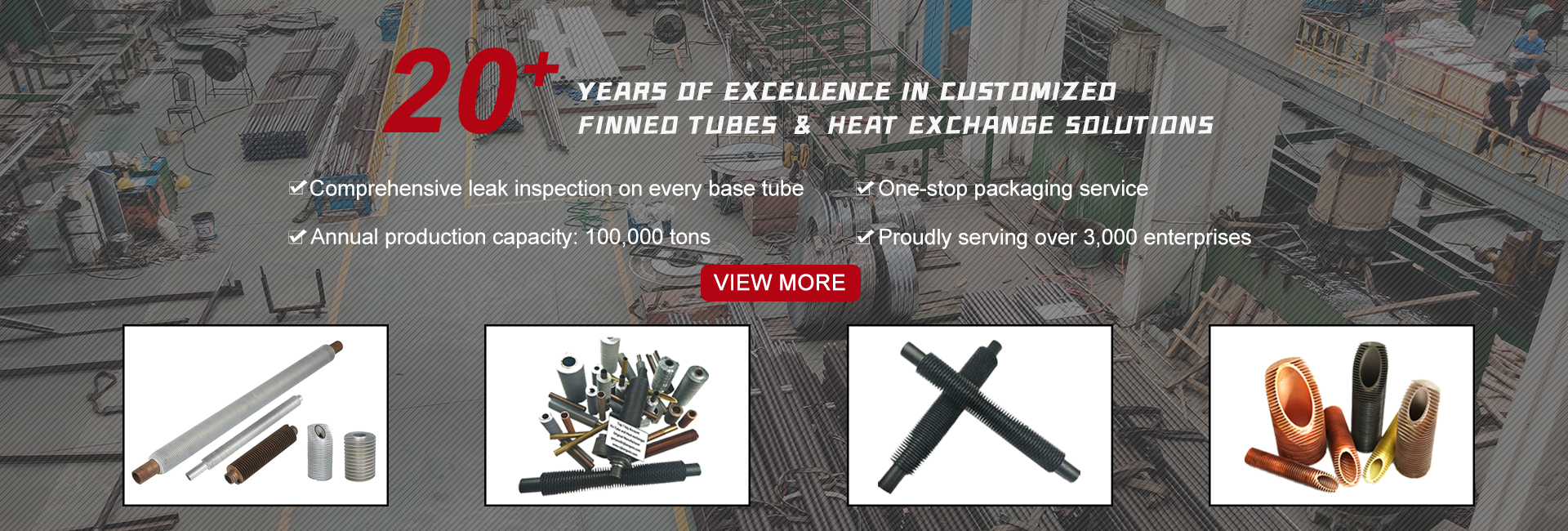

High frequency welding fin tubes are engineered for efficient heat transfer in heat exchangers, providing superior corrosion resistance for industrial applications.

2. What is a High Frequency Welding Fin Tube?

A high frequency welding fin tube is formed by welding a continuous strip of steel fins to a steel base tube using high frequency electric resistance welding, creating a strong bond for effective heat transfer and mechanical integrity.

3. Product Description

Base tube material: Carbon steel, stainless steel, alloy steel

Fin material: Carbon steel or stainless steel

Fin height: 10–20 mm (0.4–0.8 in)

Fin pitch: 2.5–8 mm (0.1–0.3 in)

4. Key Features

Metallic bond between fin and tube

High thermal conductivity

Good resistance to vibration and pressure

Long lifespan in corrosive environments

5. Technical Details

Welding method: High frequency electric resistance

Tube diameter: 19–63 mm (0.75–2.5 in)

Fin thickness: 0.8–1.5 mm (0.03–0.06 in)

Operating temperature: Up to 450 °C (842 °F)

6. Advantages

Efficient heat transfer

Improved mechanical strength

Reduced maintenance and operational costs

Customizable to various industry requirements

7. Applications

Petrochemical plants

Power boilers

Refinery heaters

Air cooled heat exchangers

Chemical equipment

8. FAQs

Q1: How long do high frequency welding fin tubes last?

A: Generally, 15–20 years with regular maintenance.

Q2: Are these tubes suitable for high-pressure systems?

A: Yes, they are designed to withstand high pressure and temperature.